2026 Best Industrial Machinery and Equipment Trends to Know?

In 2026, the landscape of industrial machinery and equipment is set to change significantly. Businesses are adapting to new technologies. Automation and AI are transforming the industry. These trends are not just about efficiency. They also aim to improve safety and reduce costs.

Sustainability plays a crucial role in this evolution. More companies prioritize eco-friendly practices. They seek machinery that minimizes waste and energy use. Innovations like 3D printing are also gaining traction. This technology allows for greater customization and reduces material waste.

However, adapting to these trends is not without its challenges. Companies must invest in training and new systems. Transitioning to advanced machinery can be costly. Some businesses struggle to keep up with rapid changes. Reflection on these issues is essential for successful integration into the market. The future of industrial machinery and equipment promises both opportunity and obstacles.

Emerging Technologies Transforming Industrial Machinery in 2026

Emerging technologies are reshaping the landscape of industrial machinery in 2026. Automation is becoming more sophisticated, minimizing human intervention in operations. Robots are now capable of performing complex assembly tasks, increasing efficiency. However, there's a noticeable gap in workforce skills. Companies struggle to find workers who can manage these advanced systems effectively.

Another trend is the integration of IoT devices. Machines are now equipped with sensors that provide real-time data analytics. This technology helps in monitoring performance and predicting maintenance needs. Yet, data security remains a concern. Many businesses face challenges in protecting sensitive information from cyber threats.

Sustainability is a key focus as well. Companies are adopting eco-friendly technologies to reduce waste. For instance, energy-efficient machines are gaining popularity. Still, many are hesitant due to the initial investment costs. Transitioning to greener operations requires careful planning and commitment. The path forward is promising, yet fraught with practical hurdles that need addressing.

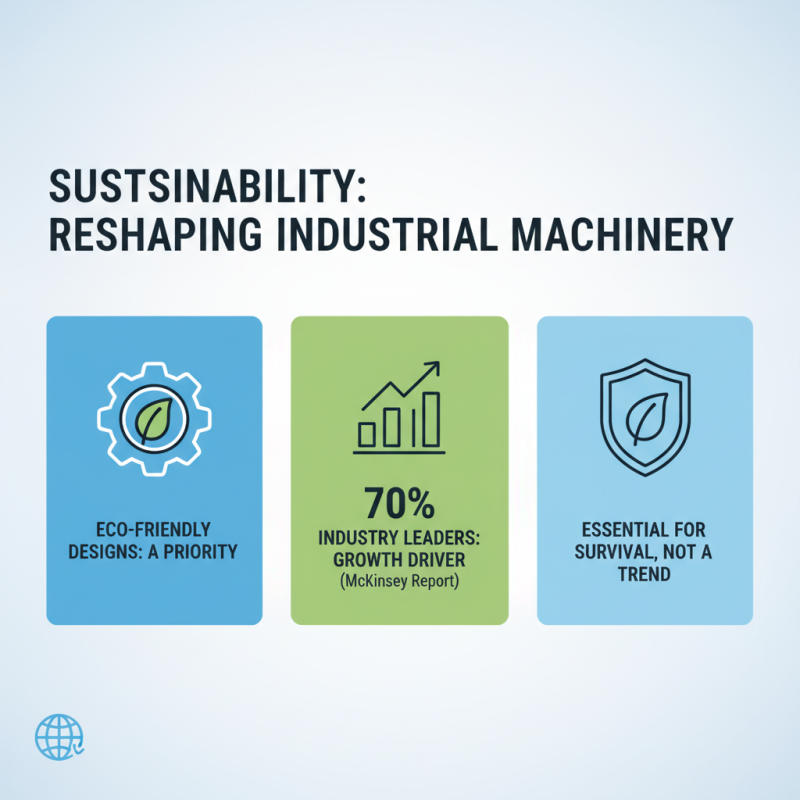

Sustainability Trends Driving Equipment Design and Manufacturing Practices

Sustainability is reshaping the industrial machinery sector. In recent years, manufacturers have prioritized eco-friendly designs. According to a McKinsey report, 70% of industry leaders believe sustainability is a key driver for future growth. It's no longer just a trend; it's essential for survival.

New technologies are at the forefront of this change. For instance, energy-efficient machinery can reduce operational costs by up to 30%. However, there remain challenges in adopting these practices. Many companies face high initial investment costs. Balancing efficiency and sustainability can be tricky. The industry must streamline operations and embrace circular economy principles to minimize waste.

Data from a recent Deloitte survey indicates that 50% of manufacturers plan to increase their investment in sustainable practices over the next three years. However, not all organizations have a clear strategy in place. Many struggle to integrate sustainability into their core operations. Developing a robust plan is crucial for long-term success. The path to sustainability is complex and requires ongoing commitment and innovation.

The Role of Automation and AI in Modern Industrial Equipment

The integration of automation and AI in industrial machinery is revolutionizing the sector. A report by McKinsey indicates that automation could increase productivity by up to 40% in manufacturing environments. This shift enables manufacturers to operate more efficiently and make data-driven decisions. AI algorithms analyze vast amounts of data, improving precision and reducing the risk of human error.

Incorporating smart sensors is essential. These devices monitor machine performance in real-time. They alert operators to potential issues before they escalate, minimizing downtime. According to a recent study by Deloitte, predictive maintenance enabled by AI can reduce maintenance costs by 25% and extend equipment lifespan.

Tips: Embrace continuous learning. Staff should regularly update their skills to work effectively with advanced machinery. Encourage a culture of innovation. Teams that are open to experimenting with new technologies tend to uncover hidden efficiencies. Remember, the path to automation is not error-free. Be prepared to face challenges as systems are integrated.

Market Shifts: Key Industries Influencing Machinery Trends by 2026

As we approach 2026, the industrial machinery and equipment landscape is shifting significantly. Various key industries are driving these changes. Manufacturing is evolving rapidly, with automation taking center stage. Smart factories are becoming the norm, integrating Internet of Things (IoT) technologies. This integration is meant to enhance productivity and reduce waste. However, not all companies are adapting well. Resistance to change creates challenges.

The construction sector is also influencing trends in machinery. There is a growing demand for sustainable equipment that minimizes environmental impact. This trend challenges manufacturers to innovate. Traditional machinery often falls short of these new expectations. Some companies struggle to implement greener technologies, risking obsolescence. Meanwhile, the agricultural industry requires machinery that can operate efficiently and sustainably. Advanced equipment that improves crop yields is in demand, yet not every player can afford such innovations.

These industry shifts require machine manufacturers to think critically. Balancing innovation with practicality is essential. Not every machinery trend will fit every company, creating a patchwork of strategies. Some may need to revisit their approach to remain competitive. The key will be adapting to these shifting demands while acknowledging the limits of technology and resources. Embracing these uncomfortable truths can pave the way for better solutions.

2026 Best Industrial Machinery Trends

This bar chart represents the projected growth percentages of key industrial machinery trends by 2026 across various sectors. The data indicates which industries are expected to drive significant changes in machinery and equipment trends.

Innovations in Safety and Ergonomics for Industrial Equipment Users

In 2026, safety and ergonomics will take center stage in industrial machinery and equipment design. As workers interact closely with machines, addressing their safety needs is paramount. Manufacturers are prioritizing user-friendly controls and better visibility. This reduces the likelihood of accidents and boosts overall productivity. Easy access to emergency stops and clear signage is now the norm.

Design improvements focus on ergonomics, too. Users are encouraged to work in a more comfortable posture. Adjustable workstations and supportive seating are becoming common. This not only enhances comfort but also reduces fatigue. However, some equipment still lacks proper ergonomic design, leading to discomfort over long hours. Feedback from users is essential for constant improvement.

Moreover, incorporating smart technology can enhance safety. Sensors can detect unsafe conditions, alerting operators immediately. However, over-reliance on technology may create new risks. Training is crucial. Workers must understand both the machines and the technology. Balancing innovation with practical usage remains a challenge in the evolving landscape of industrial equipment.

2026 Best Industrial Machinery and Equipment Trends to Know

| Trend | Description | Impact on Safety | Ergonomic Features | Adoption Rate (%) |

|---|---|---|---|---|

| Smart Machinery | Integration of IoT and AI for real-time monitoring. | Reduces workplace accidents through predictive maintenance. | Adjustable controls and automated adjustments based on user posture. | 75% |

| Augmented Reality Training | Use of AR for training operators on machinery. | Enhances safety by providing instructional overlays. | Interactive simulations that adapt to user movements. | 60% |

| Wearable Safety Devices | Devices that monitor vital signs and environmental conditions. | Immediate alerts for hazardous situations. | Designed for comfort and unobtrusiveness. | 65% |

| Robotic Assistance | Robots trained to assist human workers on the floor. | Minimizes physical strain and reduces injuries. | Ergonomically designed to work alongside humans. | 70% |

| Sustainable Design | Machinery built using environmentally friendly materials. | Improves workplace air quality and reduces toxicity. | Design focus on reducing user strain and fatigue. | 50% |

Related Posts

-

Unlocking Industrial Machinery and Equipment Insights at the 138th China Import and Export Fair 2025

-

5 Best Industrial Machine Equipment Innovations You Should Know

-

The Ultimate Guide to Choosing the Right Industrial Machinery and Equipment for Your Business

-

The Future of Industrial Supplies and Equipment in a Sustainable World

-

What is the Future of Oilfield Equipment in a Changing Energy Landscape?

-

Revolutionizing Oil Extraction: The Impact of Advanced Oil Well Machines on Production Efficiency and Safety