Best Industrial Gas Compressors for Your Applications?

In the world of industrial gas compressors, efficiency and reliability are crucial. John Smith, an expert in compressed gas technology, once said, "The right compressor can make all the difference in performance." This statement highlights the importance of selecting the best equipment for specific applications.

Industrial gas compressors play a vital role in various sectors, from manufacturing to energy. Choosing the right model can significantly impact productivity and operational costs. Many factors can affect this decision. These include application requirements, flow rates, and energy consumption.

However, the pursuit of optimal performance isn’t without challenges. Users often overlook maintenance needs or the specific demands of their operations. Neglecting these can lead to inefficiencies and increased expenses. It’s essential to evaluate options carefully and anticipate future needs. Understanding these nuances can drive better choices in industrial gas compressors.

Types of Industrial Gas Compressors and Their Applications

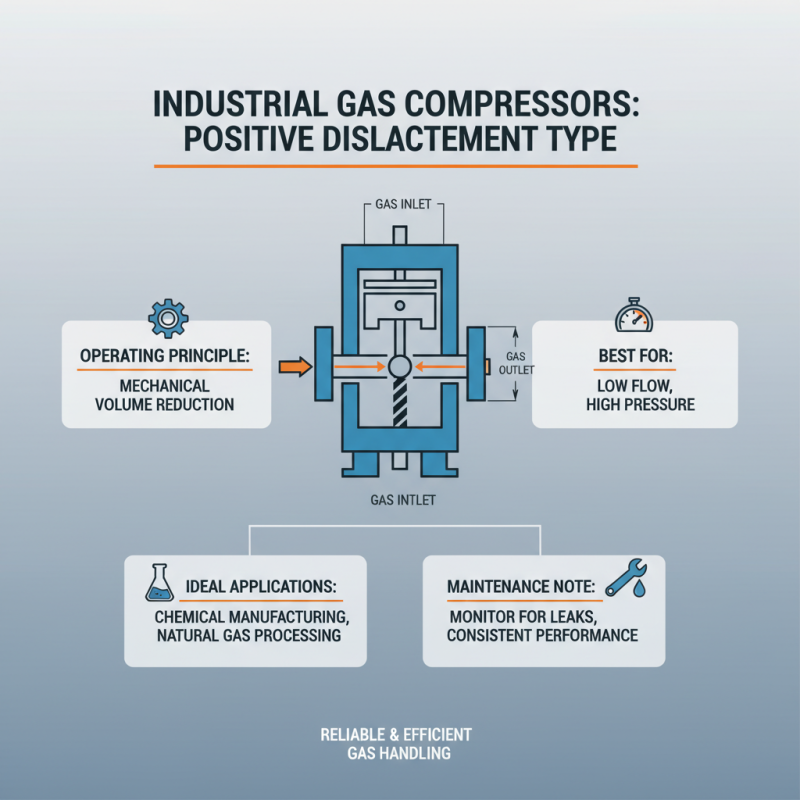

Industrial gas compressors come in various types, each tailored to specific applications. Positive displacement compressors, for example, work well for low-flow, high-pressure situations. They compress gas by reducing its volume through mechanical action. This makes them ideal for industries such as chemical manufacturing and natural gas processing. Their reliability and efficiency in handling different gases make them a popular choice. However, care must be taken to monitor for leaks, as they can often produce inconsistent results if not properly maintained.

Centrifugal compressors are another type commonly used in larger applications. These machines utilize rotating impellers to compress gas. They excel in delivering high flow rates and are typically found in oil and gas industries. While they offer significant advantages in terms of volume, they can be less efficient at low pressures. This poses a challenge for some applications. Users need to ensure they choose the right settings to avoid energy waste. A detailed understanding of specific needs is crucial in making the right choice. Evaluating the operational environment is also important, as external factors can affect performance.

Key Features to Consider When Choosing Gas Compressors

Choosing the right industrial gas compressor requires careful consideration of key features. Start by evaluating the compressor’s pressure range. This is crucial for applications that demand specific pressure levels. Additionally, look at the flow rate. This measurement shows how much gas is delivered in a given time. A higher flow rate is often necessary for larger operations.

Energy efficiency is another vital aspect. Compressors that use less energy can save costs over time. It's essential to assess the maintenance requirements as well. Some models may need frequent servicing, which can disrupt operations. Also, pay attention to noise levels. In some work environments, loud compressors can negatively impact productivity.

Compatibility with different gases is also important. Not all compressors handle every type of gas. Ensure the selected model matches your specific requirements. Lastly, consider the size and weight. A model that is too large may affect space and mobility. Reflect on your situation and what features align best with your needs.

Best Industrial Gas Compressors - Key Features Comparison

Popular Brands and Models of Industrial Gas Compressors

When selecting an industrial gas compressor, various brands and models stand out in the market. Each option has unique features and capabilities. Some compressors are designed for high efficiency, while others prioritize noise reduction. Consider the specific requirements of your application when choosing.

There are several popular models that fit different industrial needs. For instance, some compressors work well in environments requiring stable pressure and consistent output. They may lack flexibility in connectivity options, which can be frustrating. It’s essential to evaluate the trade-offs of each model carefully.

Additionally, some brands have solid reputations but might exhibit issues in specific scenarios. It's not uncommon to hear of operational hiccups, which can lead to delays. Performance metrics are crucial, but real-world feedback is often overlooked. Engaging with end-users can provide insights into the challenges faced in daily operations.

Maintenance Tips for Optimal Performance of Gas Compressors

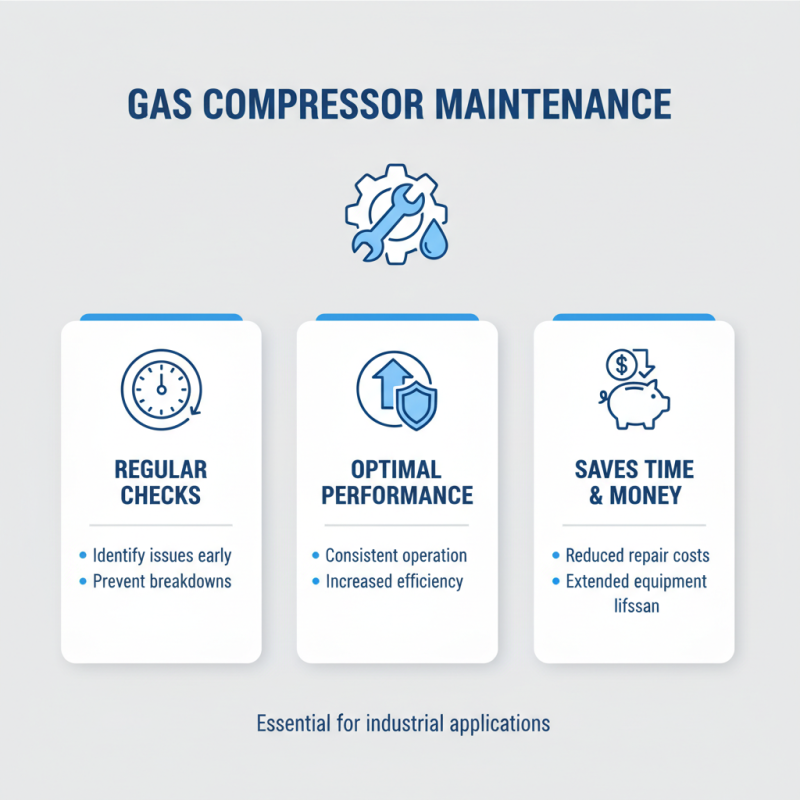

Gas compressors are essential in many industrial applications. To ensure optimal performance, proper maintenance is critical. Regular checks help identify potential issues early, saving time and money.

One crucial maintenance tip is to keep an eye on the oil levels. Insufficient oil can lead to increased wear and tear. Change the oil regularly based on the compressor’s operating conditions. This small step can significantly extend the compressor's lifespan.

Another tip involves checking for leaks. Even minor leaks can lead to inefficiencies and increased operational costs. Inspect all connections and seals frequently. Immediate repairs can prevent bigger problems down the line. Neglecting this can cause unnecessary downtime.

Don’t forget to clean the air filters as well. Clogged filters can restrict airflow and reduce efficiency. Regular cleaning can improve performance noticeably. A little routine attention can yield big rewards. It's easy to overlook these details, but they are vital for the health of your gas compressor.

Cost Considerations and Budgeting for Gas Compressor Purchases

When budgeting for industrial gas compressors, several factors come into play. The initial purchase cost can range significantly. Basic models might start around $3,000, while high-capacity units can exceed $100,000. This wide range impacts planning.

Operating costs are another critical consideration. Reports indicate that maintenance can account for up to 20% of the total expenses over a compressor's life. Regular servicing is mandatory, yet many overlook it, leading to unexpected breakdowns. This reflects a lack of foresight that could inflate costs quickly.

Energy consumption is often a hidden cost. Compressors can consume up to 30% of a facility's energy in some settings. Choosing energy-efficient models can minimize this drawback, but the upfront investment might feel steep. It's essential to analyze total lifecycle costs, not just initial prices. Balancing short-term budgeting and long-term savings might require hard decisions. Unexpected maintenance or energy costs can derail even the best-laid plans.

Best Industrial Gas Compressors for Your Applications

| Type of Compressor | Max Pressure (psi) | Flow Rate (CFM) | Power Consumption (HP) | Estimated Cost ($) | Maintenance Frequency (Months) |

|---|---|---|---|---|---|

| Rotary Screw Compressor | 150 | 100 | 25 | 15,000 | 6 |

| Piston Compressor | 175 | 50 | 10 | 8,000 | 12 |

| Centrifugal Compressor | 200 | 200 | 50 | 25,000 | 18 |

| Diaphragm Compressor | 100 | 25 | 5 | 5,000 | 24 |

| Scroll Compressor | 150 | 40 | 7.5 | 6,500 | 12 |

Related Posts

-

Top 5 Gas Compressors for Efficient Energy Solutions in 2023

-

How to Select the Right Industrial Gas Compressor for Your Business Needs

-

Unlocking Efficiency: How Industrial Gas Compressors Revolutionize Modern Manufacturing

-

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing

-

Unlocking Industrial Machinery and Equipment Insights at the 138th China Import and Export Fair 2025

-

How to Choose the Right Industrial Equipment for Your Business Needs