How to Choose the Right Industrial Equipment for Your Business Needs

Choosing the right industrial equipment is a critical decision that can significantly impact the efficiency and productivity of your business. With a myriad of options available in the market, it becomes essential to understand your specific needs and the various types of industrial equipment designed to meet those requirements. From manufacturing machinery to material handling tools, the right selection can streamline operations, reduce overhead costs, and enhance overall effectiveness.

In this guide, we will explore key considerations for selecting industrial equipment tailored to your business's unique demands. Factors such as the nature of your operations, production volume, and budget constraints will play crucial roles in determining the most suitable equipment. Additionally, we will delve into the importance of evaluating equipment quality, supplier reliability, and maintenance options to ensure a sound investment that supports your long-term goals. By making informed choices, businesses can position themselves for growth and success in an increasingly competitive landscape.

Understanding Your Business Requirements for Industrial Equipment

Understanding your business requirements is crucial when selecting the right industrial equipment. First, assess the specific tasks that the equipment needs to accomplish. This might involve evaluating production volume, the types of materials involved, and any specialized processes that your business employs. Understanding these core requirements helps narrow down the range of equipment options available and ensures that you choose tools that are well-suited for your operational needs.

Additionally, consider the scalability of the equipment. As businesses grow, their equipment needs may evolve. It's important to select equipment that can adapt to varying production levels or integrate with existing systems. Finally, do not overlook factors such as energy efficiency, maintenance requirements, and the availability of replacement parts. Evaluating these aspects will not only help in making a well-informed decision but also ensure that your investment is sustainable in the long run.

How to Choose the Right Industrial Equipment for Your Business Needs

| Equipment Type | Key Features | Business Needs | Estimated Cost | Recommended Use Cases |

|---|---|---|---|---|

| Forklift | Load capacity, durability, maneuverability | Material handling, warehouse logistics | $25,000 - $50,000 | Warehouses, construction sites |

| CNC Machine | Precision, automation, material versatility | Manufacturing parts, custom machining | $50,000 - $100,000 | Aerospace, automotive, custom fabrication |

| Industrial Dryer | Heat efficiency, capacity, material compatibility | Drying materials, textile industry | $30,000 - $60,000 | Textiles, food processing |

| Compressor | Pressure, energy efficiency, noise level | Pneumatic tools, refrigeration | $5,000 - $25,000 | Manufacturing, workshop applications |

Evaluating Different Types of Industrial Equipment Available

When evaluating different types of industrial equipment for your business needs, it is essential to consider the specific functions and tasks that the equipment will perform. Various equipment is designed for diverse applications, such as manufacturing, material handling, or processing. For instance, if your business requires heavy lifting, you might explore options like forklifts or cranes, while companies focused on assembly might need conveyors or robotic arms. Understanding the operational requirements and the environment in which the equipment will be utilized is crucial in this decision-making process.

Moreover, evaluating equipment based on efficiency, durability, and maintenance requirements can significantly affect long-term operational costs. It's important to assess the energy consumption and potential return on investment of the equipment. Additionally, consider the ease of maintenance and availability of spare parts, as this will impact downtime and serviceability. Conducting a comprehensive analysis of these factors can ensure that you select the right industrial equipment that aligns with your business goals and enhances productivity while minimizing disruptions in operations.

Assessing Quality and Reliability of Equipment Brands

When selecting industrial equipment for your business, assessing the quality and reliability of equipment brands is crucial to ensuring optimal performance and longevity. Quality can often be gauged by examining the materials used, the manufacturing process, and adherence to industry standards. Brands that invest in high-quality materials and rigorous testing tend to yield more durable products that can withstand the demands of industrial environments. Additionally, seeking out equipment that comes with certifications can help guarantee that it meets established safety and quality benchmarks.

Reliability, on the other hand, involves looking into the brand's track record and reputation in the market. Gathering feedback from other businesses, reading product reviews, and exploring case studies can provide valuable insights into how well a brand's equipment performs over time. Additionally, consider the support system the brand offers, including warranties, customer service, and ease of obtaining replacement parts. A brand that stands behind its products with strong customer support is often a better choice, as it indicates a commitment to maintaining quality and reliability even after the sale.

Determining Budget Constraints and Financing Options

When evaluating industrial equipment, assessing budget constraints and financing options is critical for ensuring your investment aligns with your business needs. According to a recent report from the National Association of Manufacturers, nearly 70% of small to medium enterprises cite budget limitations as a primary barrier to acquiring necessary equipment. Therefore, a thorough understanding of your financial capacity is essential in making informed decisions.

Tips: Before diving into purchases, create a detailed budget that includes not only the initial equipment costs but also maintenance, training, and operational expenses. Engaging with financial advisors can aid in exploring various financing options, such as leases, loans, or vendor financing plans. The Global Equipment Finance Market is projected to exceed $1 trillion by 2025, highlighting the increasing variety and accessibility of financing solutions available for businesses today.

It's also advisable to explore grants or subsidies that may be available, as many governments and organizations offer financial assistance to businesses that invest in certain technologies or equipment, particularly in sustainability efforts. Conducting a cost-benefit analysis will help clarify which financing options provide the best return on investment, ultimately leading to a more strategic choice in industrial equipment procurement.

Industrial Equipment Budget Distribution

Considering Maintenance and Support Services for Equipment

When choosing industrial equipment, it’s essential to consider not only the machinery itself but also the maintenance and support services that come with it. Effective maintenance can greatly influence the longevity and performance of your equipment, ultimately affecting your business operations. Therefore, assessing the availability and quality of support services should be a critical part of your decision-making process.

Tip: Look for suppliers who offer comprehensive support services, including training, troubleshooting, and repairs. This ensures that your staff is well-equipped to handle the equipment, minimizing downtime during emergencies. Furthermore, inquire about the supplier’s response time for service requests, as quick support can prevent costly delays in production.

Additionally, understanding the maintenance requirements of the equipment is vital. Some machinery may require regular servicing or specific conditions to operate optimally. Programs that offer routine maintenance can help keep equipment in peak condition and extend its lifespan.

Tip: Evaluate the maintenance contracts available from different suppliers. Select one that not only fits your budget but also guarantees essential services like emergency repairs and regular check-ups. This proactive approach to maintenance will help secure a stable operational environment, reducing the risk of unexpected failures.

Related Posts

-

What is an Industrie Machine and How it Transforms Modern Manufacturing

-

Exploring Innovative Examples of Industrial Supplies and Equipment for Modern Manufacturing

-

How to Optimize Your Operations with a Natural Gas Machine

-

Unlocking Industrial Machinery and Equipment Insights at the 138th China Import and Export Fair 2025

-

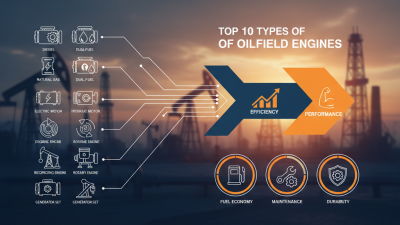

Exploring the Future of Oilfield Equipment: Innovations Transforming the Industry Landscape

-

Top 10 Oilfield Engines Must Know for Enhancing Efficiency and Performance