How to Choose the Right Natural Gas Machine for Your Business Needs

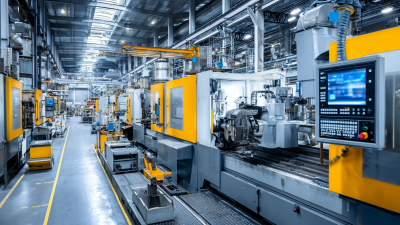

When selecting the appropriate natural gas machine for your business, it's essential to consider various factors that align with your operational needs and efficiency goals. According to a report by the American Gas Association, natural gas has become the fuel of choice for over 70% of U.S. industrial operations due to its cost-effectiveness and lower emissions compared to traditional fuels. The demand for natural gas machines is projected to grow, reflecting the industry’s shift towards more sustainable and efficient energy solutions. Evaluating specific requirements—such as energy consumption, application compatibility, and maintenance needs—will help you make an informed decision that enhances productivity and reduces overall costs. Understanding these elements is crucial to harnessing the benefits of natural gas technologies effectively, thereby positioning your business strategically in a competitive market.

Identifying Your Business Needs for Natural Gas Machines

When selecting the right natural gas machine for your business, it's essential to start by thoroughly understanding your specific operational needs. According to a report by the U.S. Energy Information Administration, natural gas consumption in industrial applications has steadily grown, reaching approximately 25% of total U.S. energy consumption by 2022. This statistic underscores the significance of tailoring your machine choice to your facility's energy demands and operational efficiency goals.

Different industries have varying requirements for natural gas machinery. For instance, manufacturing sectors may prioritize high-efficiency boilers or heaters that meet stringent emission regulations while minimizing fuel costs. A study by the American Gas Association found that businesses adopting advanced natural gas technologies could reduce operational costs by up to 30%. Therefore, it's crucial to evaluate not just the immediate benefits but also the long-term impacts on your bottom line. By aligning your business needs with the capabilities and efficiencies offered by modern natural gas machines, you can drive productivity and sustainability in your operations.

Comparing Different Types of Natural Gas Machines Available

When selecting the right natural gas machine for your business needs, it’s critical to understand the different types available and their specifications. The U.S. generator sales market reveals a division by power ratings, categorizing machines into four segments: below 75 kVA, 75-375 kVA, 375-750 kVA, and above 750 kVA. Each category serves different operational requirements, with smaller machines sufficing for low-demand applications and larger units providing robust power for heavy industrial use.

Moreover, safety considerations in gas-powered equipment cannot be overstated. Recent incidents, such as the explosion caused by a mismatch in gas sources in a water heater installation, highlight the importance of ensuring compatibility between the machine and the fuel supplied. Thoroughly assessing your specific gas type and pressure rating is crucial in avoiding such hazardous outcomes. According to industry analyses, properly matched equipment significantly reduces the risk of malfunctions and enhances operational efficiency, ultimately safeguarding both personnel and property.

How to Choose the Right Natural Gas Machine for Your Business Needs

| Machine Type | Power Output (kW) | Efficiency (%) | Typical Uses | Cost Range ($) |

|---|---|---|---|---|

| Natural Gas Generator | 20 - 200 | 85 - 95 | Backup power, Construction sites | 5,000 - 50,000 |

| Natural Gas Boiler | 30 - 1000 | 80 - 90 | Space heating, Industrial processes | 3,000 - 25,000 |

| Natural Gas Compressor | 10 - 500 | 75 - 85 | Gas transport, Refrigeration | 2,000 - 30,000 |

| Natural Gas Engine | 50 - 1000 | 90 - 98 | Transportation, Power generation | 10,000 - 100,000 |

Assessing Efficiency and Cost-Effectiveness of Gas Machines

When selecting a natural gas machine for your business needs, understanding efficiency and cost-effectiveness is vital. According to a report by the U.S. Department of Energy, the operational efficiency of natural gas engines has reached impressive levels, with many models boasting efficiency ratings exceeding 90%. This high efficiency translates to lower fuel consumption and reduced operating costs, an essential factor for businesses aiming to maximize profitability.

Cost-effectiveness is not solely about the initial investment; ongoing operational expenses play a significant role. The Natural Gas Supply Association notes that, on average, natural gas prices have remained more stable compared to other fuel sources, showing a volatility of approximately 10% over the past decade. This stability enables businesses to better forecast and manage their energy costs. Moreover, transitioning to natural gas machines can also qualify businesses for various tax incentives and rebates, further enhancing their financial appeal. By thoroughly assessing both efficiency ratings and long-term cost implications, businesses can make informed decisions that align with their operational goals.

Understanding Safety Standards and Compliance for Gas Equipment

Choosing the right natural gas machine for your business involves not only understanding the equipment itself but also ensuring compliance with safety standards. Safety is paramount in any operation utilizing gas equipment, as improper use can lead to dangerous situations. Familiarizing yourself with relevant local, national, and international safety regulations is essential to ensure that your business not only adheres to the law but also protects the health and safety of your employees and customers.

Tips for compliance include staying updated on the latest safety standards set by organizations like the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). Regular training for your staff on the safe operation of gas machines can also significantly mitigate risks. Additionally, always verify that any equipment you purchase has been certified by relevant authorities, as this guarantees that it meets necessary safety guidelines and performance standards.

Another critical aspect is conducting routine maintenance and inspections of gas machinery. These checks help identify potential hazards early and ensure that all components are functioning correctly. Implementing a strict maintenance schedule can prevent issues that may arise from wear and tear, ultimately safeguarding your business and staff.

Natural Gas Machine Efficiency Ratings

Evaluating Maintenance and Support Options for Natural Gas Machines

When selecting a natural gas machine, evaluating maintenance and support options is a crucial aspect that can influence the longevity and performance of your investment. According to a report by the Gas Technology Institute, proactive maintenance can extend equipment life by up to 30%, highlighting the importance of adequate support systems. Businesses must consider the availability of qualified technicians, spare parts, and the frequency of maintenance schedules, as these factors directly impact operational uptime and overall efficiency.

Tips for ensuring effective maintenance include establishing a partnership with a reliable service provider who offers not only routine maintenance but also emergency support. Look for providers with solid customer reviews and case studies that demonstrate their problem-solving capabilities. Additionally, consider investing in equipment that comes with a comprehensive support package, which might include extended warranties or 24/7 technical assistance.

Moreover, incorporating an asset management system can help businesses track maintenance history and predict future needs based on usage patterns. According to the U.S. Energy Information Administration, companies that embrace such systems can reduce unexpected downtime by nearly 40%. Therefore, making informed choices about maintenance support not only enhances operational efficiency but can also lead to significant cost savings in the long run.

Related Posts

-

5 Best Industrial Machine Equipment Innovations You Should Know

-

What is the Future of Oilfield Equipment in a Changing Energy Landscape?

-

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing

-

What is an Industrie Machine and How it Transforms Modern Manufacturing

-

Ultimate Guide to Selecting the Right Oil Field Machine for Your Operations

-

Addressing Common Issues with Basic Machine Shop Equipment: Solutions for Global Buyers