What is an Industrie Machine and How it Transforms Modern Manufacturing

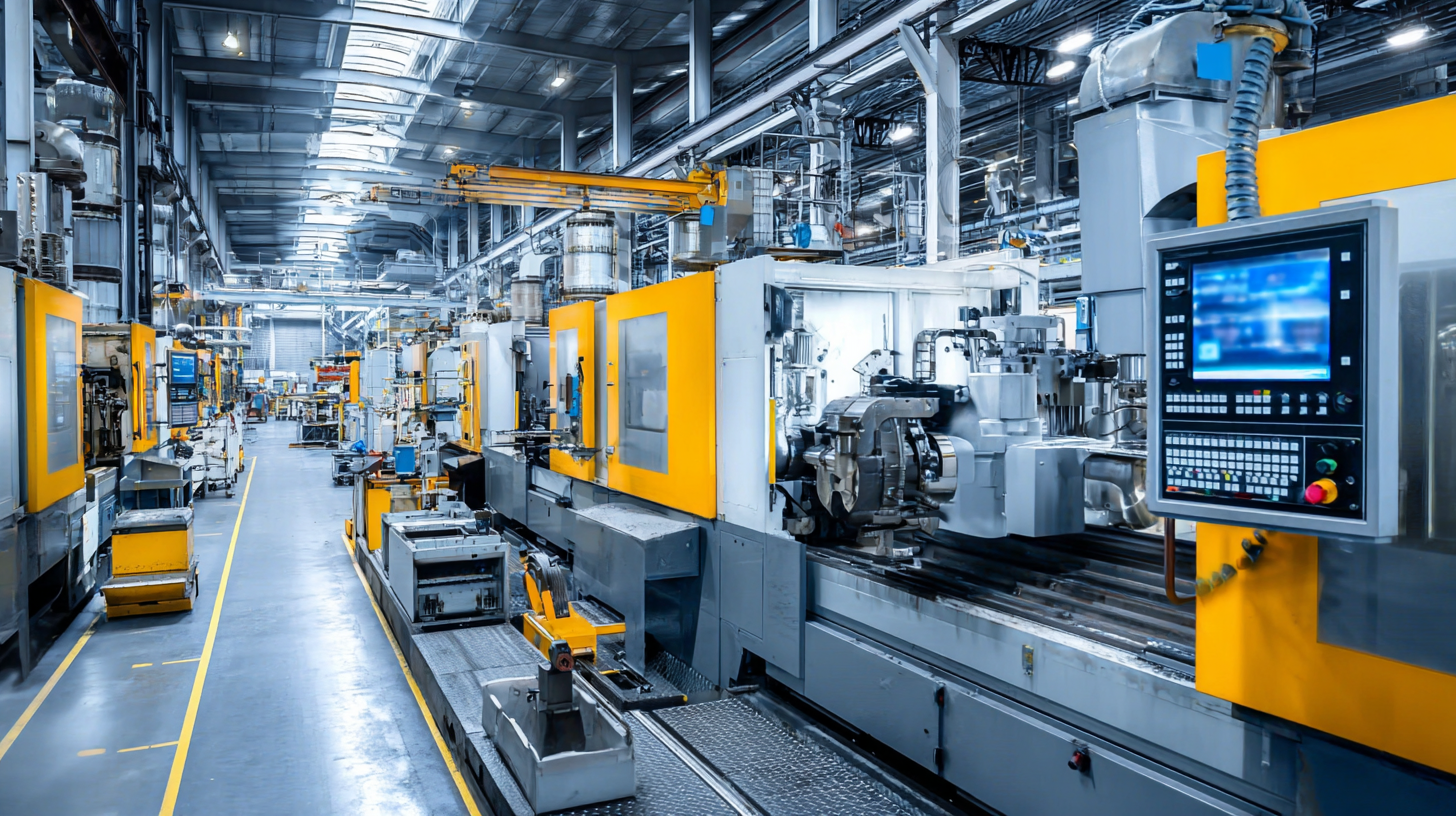

In today's rapidly evolving manufacturing landscape, the term "industrie machine" has become synonymous with innovation and efficiency. According to a report by McKinsey, advanced manufacturing technologies, including Industrie 4.0 automation and smart machinery, have the potential to increase productivity by up to 30% while significantly reducing operational costs. These machines leverage cutting-edge technologies such as artificial intelligence, IoT, and big data analytics to optimize production processes and enhance product quality. As industries worldwide strive to remain competitive, the integration of Industrie machines is not just a trend; it is a critical necessity for achieving scalability and sustainability. This blog will explore how these sophisticated machines are not only transforming traditional manufacturing paradigms but also paving the way for a more intelligent and interconnected future.

Understanding Industrie Machines: Definition and Functionality

Industrie machines represent a pivotal shift in modern manufacturing, defined as advanced automated systems integrating software, robotics, and artificial intelligence. These machines enhance production efficiency by streamlining processes, minimizing human error, and optimizing resource allocation. For example, a recent report noted that companies utilizing Industrie 4.0 technologies could increase productivity by up to 30%, ultimately leading to significant cost savings and improved product quality.

Industrie machines represent a pivotal shift in modern manufacturing, defined as advanced automated systems integrating software, robotics, and artificial intelligence. These machines enhance production efficiency by streamlining processes, minimizing human error, and optimizing resource allocation. For example, a recent report noted that companies utilizing Industrie 4.0 technologies could increase productivity by up to 30%, ultimately leading to significant cost savings and improved product quality.

As industries evolve, real-time communication capabilities have become crucial. Companies like Siemens are leveraging advanced AI systems to facilitate collaboration between frontline workers and engineers, enabling swift problem-solving. This cross-functional approach is essential in maintaining competitive advantage in the fast-paced manufacturing landscape.

Tips:

- Embrace software advancements; they are becoming the key differentiators in sectors such as automotive manufacturing.

- Invest in training for workforce adaptability; the integration of AI is reshaping roles and requiring new skills.

- Monitor technological trends regularly, as they can significantly influence operational efficiency and market positioning.

The Evolution of Industrie Machines: From Traditional Tools to Automation

Industrie machines have drastically evolved from traditional tools to advanced automated systems, marking a revolutionary transformation in modern manufacturing. Historically, manufacturing processes relied heavily on manual labor and simple machinery, which limited efficiency and scalability. However, as industries began to embrace technological innovations, the introduction of automated machinery revolutionized production lines, enhancing both speed and accuracy. This shift not only optimized resources but also reduced human error, paving the way for increased productivity.

Tips for manufacturers looking to transition from traditional tools to automated systems include investing in employee training to ensure a smooth transition. Understanding the capabilities and limitations of new machinery is essential for maximizing efficiency. Additionally, scheduling regular maintenance for automated systems can prevent costly downtime and extend the lifespan of the equipment. Embracing data analytics tools can also provide insights into production performance, guiding further improvements and innovations within the manufacturing process.

Transformation of Manufacturing Through Industrie Machines

Key Technologies Behind Industrie Machines in Modern Manufacturing

Industrie machines represent a significant evolution in modern manufacturing, integrating cutting-edge technologies that enhance efficiency and productivity. Among these technologies, the Internet of Things (IoT) plays a crucial role. By connecting machines to the internet, manufacturers can monitor performance in real time, predict maintenance needs, and optimize operations. This connectivity not only streamlines production but also allows for quick adjustments based on real-time data.

Tip: When implementing IoT in your manufacturing processes, ensure that you have robust cybersecurity measures in place to protect sensitive data from potential breaches.

Another key technology is artificial intelligence (AI), which drives intelligent automation. AI algorithms can analyze vast amounts of data, enabling machines to learn from patterns and improve operational efficiency. This not only reduces human error but also minimizes downtime, as AI can forecast issues before they escalate into significant problems.

Tip: Consider starting with a pilot project that integrates AI solutions, allowing your team to assess their effectiveness and scalability before a full-scale rollout. This minimizes risk while maximizing the potential benefits of AI in your manufacturing processes.

Benefits of Industrie Machines: Enhancing Efficiency and Accuracy

Industrie machines are revolutionizing the manufacturing landscape by enhancing operational efficiency and precision. In today's fast-paced industrial environment, companies are constantly seeking ways to streamline processes and minimize waste. Industrie machines, equipped with advanced automation technologies, enable manufacturers to optimize production workflows, thereby reducing downtime and improving overall productivity. These machines can perform repetitive tasks with unparalleled speed and consistency, ensuring that output quality remains high while minimizing human errors.

The accuracy offered by industrie machines is another significant advantage in modern manufacturing. With the integration of sophisticated sensors and control systems, these machines can achieve remarkable precision in production processes. This level of accuracy is critical, especially in industries such as aerospace, automotive, and electronics, where even the smallest deviation can lead to costly defects. By using industrie machines, manufacturers can ensure that every component meets stringent specifications, thus enhancing product reliability and customer satisfaction. Overall, the innovative capabilities of industrie machines not only boost efficiency but also pave the way for higher standards of quality in modern manufacturing.

Challenges and Future Trends in Industrie Machine Adoption

The adoption of Industrie machines in modern manufacturing brings significant challenges that companies must navigate to fully harness their potential. Integrating advanced technologies like IoT, AI, and robotics demands a foundational shift in operations and workforce training. Companies often face resistance to change, as employees may be apprehensive about new technologies replacing traditional methods. Therefore, fostering a culture of adaptability and continuous learning is essential.

Tip: Invest in comprehensive training programs to enhance employee skills and ease the transition to advanced machinery. Regular workshops and hands-on experience can demystify the technology and empower the workforce.

Looking toward the future, the trends in Industrie machine adoption indicate a growing reliance on data analytics for optimizing production processes. By leveraging big data, manufacturers can predict equipment failures, streamline operations, and significantly reduce downtime. However, this also raises concerns about data security and the need for robust cybersecurity measures.

Tip: Implement a layered security approach to protect sensitive data while utilizing smart machines. Regularly update your security protocols to counter emerging threats and ensure a sustainable manufacturing environment.

Related Posts

-

The Ultimate Guide to Choosing the Right Industrial Machinery and Equipment for Your Business

-

Uncovering the Advantages of Industrial Machine Equipment in Enhancing Global Supply Chain Efficiency

-

Exploring Innovative Examples of Industrial Supplies and Equipment for Modern Manufacturing

-

What is the Future of Oilfield Equipment in a Changing Energy Landscape?

-

Mastering Industrial Shop Equipment A Comprehensive Guide for Beginners

-

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing