What is Natural Gas Compression Equipment and How Does It Work

Natural gas compression equipment plays a vital role in the energy sector. According to the U.S. Energy Information Administration, the natural gas market is projected to grow by 50% by 2030. This increase in demand necessitates efficient transportation and storage solutions. Compressors are essential in overcoming the challenges of long-distance gas transmission. They pressurize natural gas to enable it to flow through pipelines.

Natural gas compression technology has advanced significantly. Newer systems achieve higher efficiency and reduce emissions. Various types of compressors, such as reciprocating and centrifugal, cater to different operational needs. Each design has its strengths and weaknesses, requiring careful consideration when selecting equipment. For instance, while reciprocating compressors are widely used due to their reliability, they may not be the best option for larger volumes.

Despite the improvements, there are still challenges facing the industry. Maintenance issues can arise, sometimes leading to unplanned downtime. Indeed, Effective operation of natural gas compression equipment is crucial for maximizing output. The balance between efficiency, cost, and environmental impact requires ongoing evaluation. Such reflection ensures the industry adapts to growing demands and regulatory standards.

What is Natural Gas Compression Equipment?

Natural gas compression equipment plays a crucial role in the energy sector. This equipment is essential for transporting gas over long distances. It ensures that the gas remains under high pressure. High pressure allows the gas to flow smoothly through pipelines.

There are different types of compressors used in the industry. Each one serves a unique purpose. Positive displacement compressors are common. They trap gas and compress it. However, they can be less efficient at larger scales. On the other hand, dynamic compressors use rotating blades. These can be more efficient for high-volume applications. Still, they may require more maintenance.

Setting up compression systems is not always straightforward. Each installation faces unique challenges. For example, noise pollution can be an issue in residential areas. Additionally, ensuring safety standards is vital. Operators must constantly monitor operations. The equipment needs regular checks. Even small issues can lead to safety hazards.

Types of Natural Gas Compressors Used in the Industry

Natural gas compressors play a crucial role in the industry. They come in various types, each suited for specific applications. Centrifugal compressors are widely used for large volume gas transport. They operate on the principle of converting kinetic energy into pressure. These compressors can handle large flows efficiently, making them ideal for natural gas pipelines.

Another type is the positive displacement compressor. This type compresses gas by mechanically decreasing its volume. It includes rotary screw and diaphragm compressors. Rotary screw compressors are favored for their reliability and ease of maintenance. Diaphragm compressors, while less common, are valued for their ability to handle corrosive gases and offer higher purity levels.

Each compressor type has strengths and weaknesses. Centrifugal compressors might not perform well at low flow conditions. Positive displacement compressors can be more complex and may require more maintenance. It’s essential to consider the specific requirements of the application when choosing the right type. The right choice can significantly influence efficiency and operational costs.

Principles of Operation for Natural Gas Compression Equipment

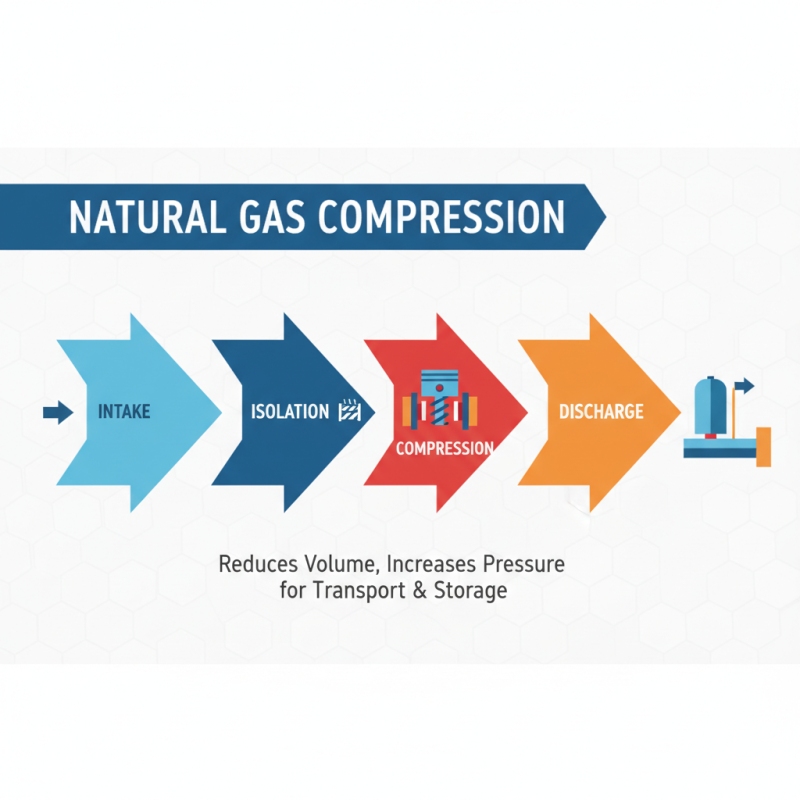

Natural gas compression equipment plays a crucial role in transporting and storing natural gas. Understanding its principles of operation helps in grasping how it functions. This equipment relies on a few key processes: intake, isolation, compression, and discharge. During intake, natural gas enters the compressor, where it is isolated from the surrounding atmosphere. It is then compressed, which reduces its volume and increases pressure. Finally, the high-pressure gas is discharged for transportation or storage.

Many factors influence the efficiency of natural gas compression. The type of equipment, ambient conditions, and even maintenance practices can impact performance. Regular maintenance is essential. Keep an eye on component wear and tear. This helps maintain optimal efficiency.

Remember that safety is paramount. Compressing gas can be risky. Always follow safety guidelines and protocols. Consider investing in monitoring systems. They can alert you to any irregularities. This way, you ensure the reliable operation of your compression equipment.

Applications of Compressed Natural Gas in Various Sectors

Compressed natural gas (CNG) plays a vital role in various sectors. It's commonly used in transportation, powering buses and vehicles. These vehicles produce lower emissions than traditional fuels. This shift aids in reducing air pollution in urban areas. Many city initiatives promote CNG as a cleaner option. However, the infrastructure for refueling stations is still growing. Some regions struggle with availability.

In industrial applications, CNG is used for heating and as a fuel source. Factories often switch to CNG to cut costs and reduce emissions. This change can lead to significant savings over time. However, retrofitting equipment can be a challenge for some businesses. They may need to focus on long-term benefits versus upfront costs.

CNG is also applied in power generation. It provides a more efficient and cleaner energy source compared to coal. Yet, transitioning to CNG isn't without issues. Some communities resist the change due to potential environmental concerns. Addressing these worries is essential for broader acceptance. The potential benefits are significant, but not without hurdles.

Maintenance and Safety Considerations for Compression Equipment

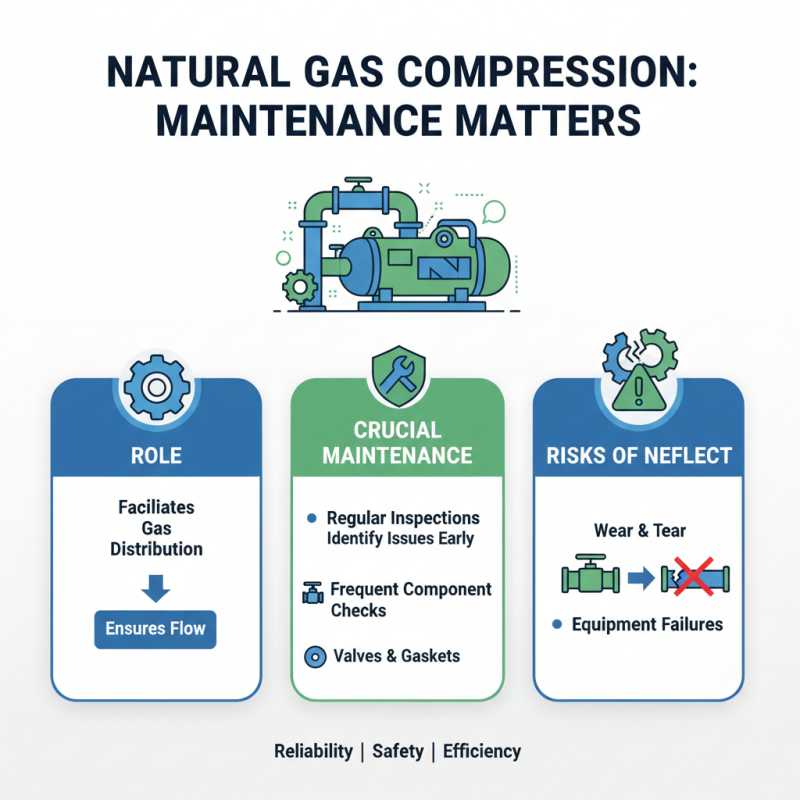

Natural gas compression equipment plays a vital role in the distribution of gas. Proper maintenance of this equipment is crucial. Regular inspections help identify potential issues. Components like valves and gaskets should be checked frequently. Over time, wear and tear can lead to failures.

Cleaning is essential. Keep the equipment free of debris. Lubrication of moving parts lowers friction. This helps prevent overheating. Operators must be trained to recognize unusual noises or vibrations. Such signs often indicate a problem. It's a good practice to note these changes.

Safety should never be taken lightly. Equipments must adhere to safety standards. Use protective gear when operating or maintaining the equipment. Emergency procedures should be well understood. Regular safety drills can help reinforce these protocols. Sometimes, complacency can lead to accidents. Remind everyone to remain vigilant.

Related Posts

-

Why Natural Gas Compression Equipment Is Essential for the Energy Industry

-

How to Optimize Your Operations with a Natural Gas Machine

-

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing

-

How to Choose the Right Industrial Equipment for Your Business Needs

-

Addressing Common Issues with Basic Machine Shop Equipment: Solutions for Global Buyers

-

Top Oilfield Production Equipment Trends to Watch in 2025