Top Oilfield Production Equipment Trends to Watch in 2025

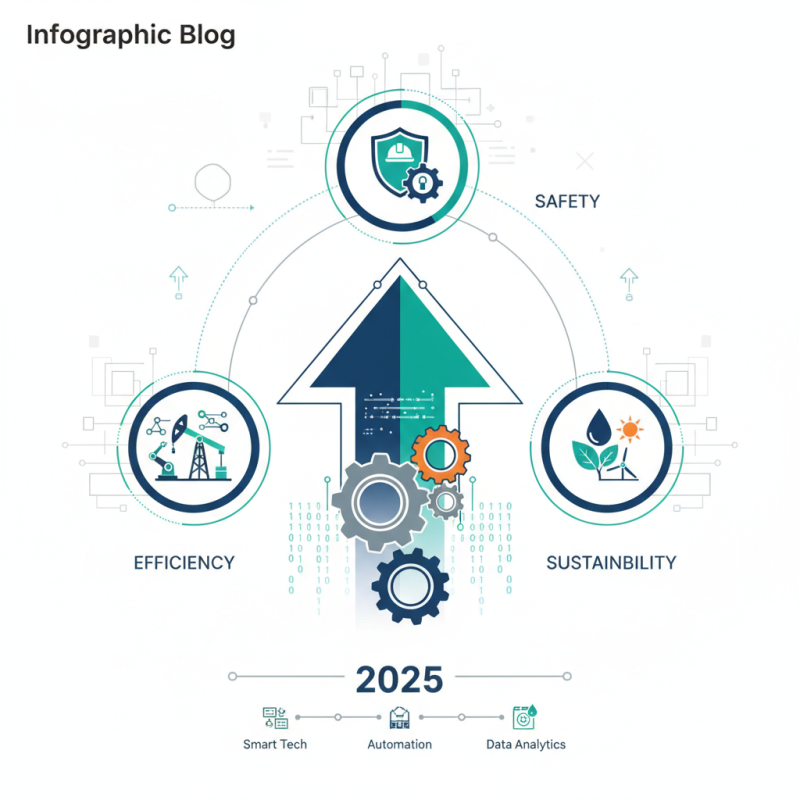

As the global energy landscape continues to evolve, 2025 is poised to bring transformative changes to oilfield production equipment. The increasing demand for efficiency, safety, and sustainability is driving innovation and reshaping the way oil and gas operators approach their production processes. In this context, understanding the emerging trends in oilfield production equipment is crucial for stakeholders aiming to remain competitive and compliant in an ever-changing environment.

Technological advancements are at the forefront of these trends, with smart technologies, automation, and data analytics playing significant roles in optimizing production. These innovations not only enhance operational efficiency but also contribute to reduced environmental impact, addressing the industry's growing concerns regarding climate change and resource management. As we look ahead, it is imperative for industry professionals to stay informed about these developments and their implications for future production strategies.

Furthermore, the focus on sustainable practices is expected to intensify, leading to the adoption of oilfield production equipment that minimizes waste and maximizes resource utilization. Companies that prioritize sustainability while leveraging new technologies will likely gain a competitive edge in the market. This article will explore the key trends anticipated in 2025 related to oilfield production equipment, providing insights into how they will shape the future of the industry.

Emerging Technologies Shaping Oilfield Production Equipment in 2025

As we look towards 2025, the oilfield production equipment landscape is poised for significant transformation driven by emerging technologies. One of the most notable advancements is the integration of artificial intelligence and machine learning. These technologies enable predictive maintenance by analyzing real-time data from various equipment. This leads to reduced downtime and optimized production processes, as operators can preemptively address issues before they escalate into costly failures.

Moreover, the adoption of automation is set to revolutionize oilfield operations. Automated systems and robotics will streamline drilling and production tasks, enhancing efficiency and safety. The implementation of remote operations will allow for monitoring and control of equipment from afar, thereby reducing the need for on-site personnel in hazardous environments. This shift not only improves operational efficiency but also mitigates risks associated with human involvement in these demanding settings.

Lastly, advancements in sensor technology are enabling more accurate monitoring of equipment performance and environmental impact. IoT-enabled devices will gather vast amounts of data, providing real-time insights that can help to minimize waste and enhance sustainability practices in oilfield operations. As these technologies converge, they will redefine the capabilities of oilfield production equipment, ensuring that the industry is better equipped to meet the challenges of the future.

Top Oilfield Production Equipment Trends to Watch in 2025

Innovations in Automation and Control Systems for Oil Production

The oil and gas industry is on the brink of a technological revolution, particularly in the realm of automation and control systems for oil production. As operators seek to enhance efficiency and minimize operational costs, innovations in automation are becoming paramount. The integration of advanced sensors, artificial intelligence, and machine learning algorithms allows for real-time monitoring and optimization of production processes. These technologies enable predictive maintenance, which significantly reduces downtime and extends the life of critical equipment.

Furthermore, the shift toward digital oilfields is transforming the way companies manage their resources. Automated control systems streamline operations by managing workflows seamlessly and ensuring that oil production conforms to optimal safety and efficiency standards. This digital transition not only improves accuracy and response times but also fosters better decision-making through data analytics. As 2025 approaches, the continued evolution of these systems promises to increase productivity and sustainability in oil production, positioning the industry for a more efficient and resilient future.

Sustainability Trends Impacting Oilfield Equipment Development

The oilfield production equipment sector is undergoing a significant transformation influenced by sustainability trends. As the industry moves toward greener practices, oilfield operators are increasingly investing in technologies that minimize environmental impact. According to a report by the International Energy Agency, global investments in renewable energy, including wind and solar, are projected to double by 2025, further emphasizing the shift toward sustainability within the oil and gas sector.

One key trend is the integration of advanced monitoring systems that enhance energy efficiency and reduce emissions. For instance, data analytics tools can optimize drilling operations and equipment usage, allowing companies to lower their carbon footprints. A study from the Society of Petroleum Engineers indicates that employing such technologies can lead to a 20-30% reduction in greenhouse gas emissions in oilfield operations.

Tip: Companies should consider investing in smart technologies that provide real-time data, enabling proactive adjustments to operations for better efficiency and sustainability outcomes.

Moreover, there is a noticeable shift towards using environmentally sensitive materials in oilfield production equipment. Research published in the Journal of Petroleum Technology highlights that over 40% of NOCs (National Oil Companies) are now prioritizing sustainability in their procurement processes. This trend signifies a broader commitment to reducing the environmental impact of oil extraction, which not only aligns with global sustainability goals but also enhances corporate reputations among increasingly eco-conscious investors.

Tip: Emphasizing the use of green materials in projects can improve public perception and potentially attract investment from stakeholders interested in sustainable practices.

The Role of Data Analytics in Optimizing Oilfield Operations

Data analytics is set to play a pivotal role in optimizing oilfield operations by 2025, as the industry continues to embrace digital transformation. According to a report by the International Energy Agency (IEA), the integration of data analytics can increase production efficiency by up to 15% through enhanced decision-making processes. By leveraging various analytical tools, operators can gain deep insights into resource management, equipment performance, and operational workflows, which ultimately leads to significant cost savings and improved productivity.

In addition, the use of predictive analytics in the oilfield can mitigate operational risks and enhance safety measures. A study published by Deloitte indicates that the adoption of predictive maintenance models can reduce unplanned downtime by 25%, which is crucial in a sector where equipment failure can lead to substantial financial losses. Furthermore, real-time data analysis allows companies to monitor environmental conditions and respond swiftly to changes, thus ensuring compliance with regulatory standards while optimizing drilling and production schedules. As the demand for energy continues to rise, the role of data analytics in refining oilfield operations will undoubtedly become more critical, making it a trend worth watching in the coming years.

Future Challenges and Opportunities in Oilfield Production Equipment

As we look ahead to 2025, the oilfield production equipment sector is at a critical juncture, facing a host of challenges and opportunities driven by technological advancement and changing market dynamics. According to the 2022 Market Research Report by GlobalData, the global oilfield production equipment market is projected to reach USD 152 billion by 2025, growing at a CAGR of 3.5%. This growth is indicative of the increasing demand for efficient and sustainable production solutions amidst evolving regulatory environments and environmental concerns.

One of the prominent challenges is the need for enhanced operational efficiency and sustainability in oil extraction processes. The International Energy Agency (IEA) emphasizes that to meet the net-zero emission targets set for 2050, the industry must innovate and adopt more eco-friendly technologies, such as advanced drilling techniques and digital solutions that optimize resource management. Additionally, the integration of IoT (Internet of Things) and AI-driven analytics into production equipment is transforming traditional practices, making it possible to monitor equipment health in real-time and minimize downtime, thus presenting a significant opportunity for stakeholders to invest in these technologies for improved productivity.

Conversely, global political and economic uncertainties can hinder investment in oilfield production equipment. The ongoing fluctuations in oil prices create a volatile environment that affects capital spending. However, with the increasing shift towards energy diversification and the rise of renewable energy sources, there is an opportunity for oilfield production equipment suppliers to pivot towards hybrid solutions. By integrating renewables with traditional oil production methods, stakeholders can appeal to a broader market while addressing environmental concerns, positioning themselves favorably as the industry evolves over the next decade.

Related Posts

-

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing

-

5 Best Industrial Machine Equipment Innovations You Should Know

-

Best Natural Gas Engines for Efficient Power Generation Driven by 2023 Trends

-

Unlocking Efficiency: How Industrial Gas Compressors Revolutionize Modern Manufacturing

-

Ultimate Guide to Selecting the Right Oil Field Machine for Your Operations

-

Essential Guide to Selecting the Right Industrial Pumps and Machines for Your Business