How to Select the Right Industrial Gas Compressor for Your Business Needs

When it comes to optimizing operational efficiency, the selection of the right industrial gas compressors is critical for businesses across various sectors. According to a report by the International Compressors Association, the global market for industrial gas compressors is projected to reach $10 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.5%. With the increasing demand for energy-efficient and reliable gas supply systems, understanding the specific needs of your operations is essential. Industrial gas compressors not only impact productivity but also influence energy costs and environmental footprints. Therefore, businesses must evaluate their specific requirements, including pressure, flow rate, and gas type, to choose an appropriate compressor that aligns with their long-term operational goals. In this context, a well-informed decision can result in significant cost savings and enhanced performance.

Understanding Your Business’s Compressed Air Requirements

Understanding your business’s compressed air requirements is crucial in selecting the right industrial gas compressor. Compressed air is often referred to as the fourth utility, following electricity, water, and natural gas, and it plays a vital role in various industries, from manufacturing to food processing.

According to a report by the Compressor Association, approximately 70% of industrial facilities rely on compressed air systems, highlighting their importance in operational efficiency.

To accurately determine your compressed air needs, begin by assessing the total air consumption of your tools and equipment. The Air Compressors Market report indicates that businesses should calculate their air demand in cubic feet per minute (CFM) to ensure they select a compressor that meets their maximum requirements without overexerting the system. Additionally, consider factors such as the duty cycle, which affects the compressor’s lifespan—it's recommended to operate at 75% of its capacity for optimal performance and longevity. This means for a process requiring 40 CFM, a compressor rated for at least 53 CFM would be ideal.

Furthermore, pay attention to the pressure requirements inherent to your applications. The Compressed Air and Gas Institute states that most manufacturing processes operate within a range of 80-100 psi, but specific applications may require higher pressure settings. Understanding these variables will enable you to invest in a compressor that not only meets current demands but is also adaptable for future growth and efficiency improvements.

Evaluating Different Types of Industrial Gas Compressors

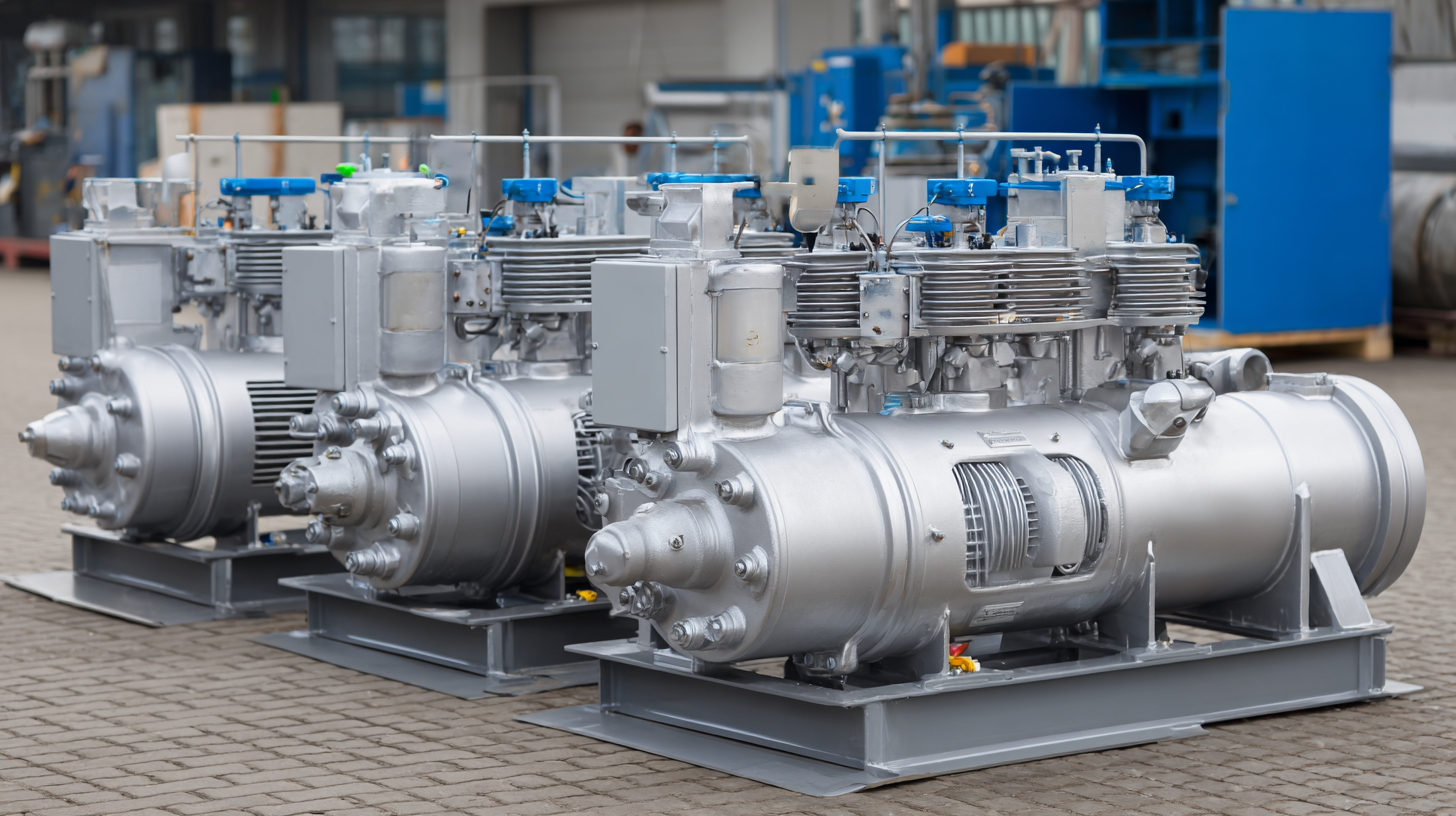

When evaluating different types of industrial gas compressors, it is essential to consider the specific requirements of your business. The most common types include reciprocating, rotary screw, and centrifugal compressors.

Reciprocating compressors are known for their high efficiency and ability to handle high-pressure applications, making them ideal for businesses that require large amounts of compressed gas in a short time.

On the other hand, rotary screw compressors offer continuous operation with lower maintenance costs, making them suitable for industries that need a steady supply of gas over prolonged periods.

Reciprocating compressors are known for their high efficiency and ability to handle high-pressure applications, making them ideal for businesses that require large amounts of compressed gas in a short time.

On the other hand, rotary screw compressors offer continuous operation with lower maintenance costs, making them suitable for industries that need a steady supply of gas over prolonged periods.

Additionally, centrifugal compressors excel in high-flow applications and are typically used in larger industrial setups. They provide a compact solution with fewer moving parts, which can reduce wear and tear, leading to lower operational costs. Each type has its advantages and disadvantages, influenced by factors such as the required flow rate, pressure, and energy efficiency. By carefully assessing the intended application and growth projections, you can determine which compressor type aligns best with your business objectives.

Factors to Consider: Capacity, Efficiency, and Maintenance Needs

When selecting an industrial gas compressor, three primary factors must be considered: capacity, efficiency, and maintenance needs. Capacity is crucial as it directly correlates with your operational requirements. According to a report by the Compressed Air and Gas Institute (CAGI), an adequately sized compressor should meet at least 90% of your peak demand without frequent cycling, which can lead to increased wear and tear. Understanding your specific capacity requirements enables you to choose a compressor that not only fulfills your immediate needs but also accommodates potential future growth.

Efficiency is another key aspect. As energy costs soar, it becomes imperative to select a compressor that maximizes output while minimizing energy consumption. The U.S. Department of Energy states that optimizing compressor efficiency can lead to savings of up to 30% in energy costs. Look for models with high Energy Efficiency Ratings (EER) and consider options like variable speed drives (VSD), which adjust motor speed to match air demand, further enhancing efficiency.

Lastly, maintenance needs should not be overlooked. A compressor that requires more frequent upkeep can incur significant operational costs over time. Research by the International Society of Automation suggests that proactive maintenance, including regular inspections and timely part replacements, can enhance compressor lifespan and performance by up to 25%. Therefore, choosing a compressor with a robust support system and accessible replacement parts can alleviate long-term maintenance burdens, ensuring smooth and efficient operation for your business.

Industrial Gas Compressor Selection: Key Considerations

Assessing Energy Consumption and Operating Costs

When selecting an industrial gas compressor, assessing energy consumption and operating costs is crucial. Energy efficiency directly impacts the bottom line; a compressor that consumes excessive power can significantly inflate operational expenses. It is essential to examine not only the initial purchase price but also the long-term costs associated with energy usage. Look for compressors that offer high efficiency ratings and variable speed drives, which adjust power consumption based on demand, thereby minimizing energy waste.

Additionally, another critical aspect to consider is maintenance costs. Reliable compressors that require minimal downtime and fewer repairs can reduce operational disturbances and extend the lifespan of equipment. Investing in units with advanced monitoring systems can help track performance, flagging inefficiencies early. Therefore, a thorough analysis of both energy consumption and ongoing operating costs will ensure that businesses select a compressor that aligns with their operational needs while supporting cost-effective practices.

Making the Final Decision: Budgeting and Supplier Support Options

When selecting the right industrial gas compressor, budgeting is a crucial aspect that can significantly impact your business's operational efficiency. One common mistake is underestimating total costs, which can include maintenance, energy consumption, and potential downtime. To avoid this, conduct a comprehensive cost analysis that incorporates both initial purchase price and long-term operational expenses. This approach ensures you invest in equipment that not only fits your budget but also meets your production needs effectively.

Tips: Always allocate funds for potential upgrades or adjustments in your compressor’s capacity. Gas demand can fluctuate, and having the flexibility to expand your system can save you from more significant expenses in the long run.

Supplier support options play a pivotal role in the long-term success of your investment. A reliable supplier should offer not just the initial purchase but also ongoing technical support, maintenance services, and spare parts availability. Before making a decision, evaluate each supplier’s service agreements and their reputation in the industry. This additional layer of support can minimize disruptions and extend the lifespan of your compressor.

Tips: Look for suppliers who provide training and resources for your staff, ensuring they can efficiently operate and maintain the compressor, further enhancing your operational stability.

Related Posts

-

Top Strategies for Maximizing Efficiency with Machine Shop Tools and Equipment in Modern Manufacturing

-

What is the Future of Oilfield Equipment in a Changing Energy Landscape?

-

Exploring Innovative Examples of Industrial Supplies and Equipment for Modern Manufacturing

-

Uncovering the Advantages of Industrial Machine Equipment in Enhancing Global Supply Chain Efficiency

-

Essential Guide to Selecting the Right Industrial Pumps and Machines for Your Business

-

The Ultimate Guide to Choosing the Right Industrial Machinery and Equipment for Your Business