Top 10 Oilfield Engines Must Know for Enhancing Efficiency and Performance

In the ever-evolving landscape of the oil and gas industry, the efficiency and performance of oilfield engines play a pivotal role in driving productivity and reducing operational costs. With the increasing demand for energy and the complexity of modern extraction methods, it is crucial for operators to be well-versed in the capabilities of different types of oilfield engines. These engines are not merely mechanical components; they represent the backbone of operations, powering everything from drilling rigs to pumping systems, and a thorough understanding of their functionalities can significantly enhance operational success.

As we delve into the ten essential oilfield engines that industry professionals must know, it is important to recognize the unique features that each type brings to the table. These engines are designed to withstand the harsh conditions typically found in oilfields, demonstrating durability and reliability that are critical for maintaining productivity. By focusing on key aspects such as fuel efficiency, maintenance requirements, and overall performance, operators can make informed decisions that optimize their asset usage and ensure a more streamlined production process. This exploration will not only highlight the engines themselves but also provide insights into how they contribute to the broader goals of efficiency and enhanced performance in oilfield operations.

Overview of Oilfield Engines and Their Importance in Operations

Oilfield engines play a crucial role in the efficiency and performance of oil production operations. These engines are designed to handle the demanding requirements of oilfields, providing the necessary power for drilling, pumping, and extraction processes. Their reliability and efficiency directly impact the operational costs and overall productivity of oilfield activities, making it essential for operators to understand the significance of these engines in their operations.

When selecting an oilfield engine, consider the environmental conditions and specific operational needs of your site. Opt for engines that offer fuel efficiency and lower emissions, as these features can lead to significant cost savings and a smaller environmental footprint. Additionally, implementing regular maintenance schedules ensures that engines run optimally, preventing unexpected downtime and costly repairs.

Another tip for enhancing performance is training personnel on the latest technologies and best practices in oilfield engine operation. Well-informed operators can make real-time adjustments and improvements, leading to increased efficiency. Staying updated with advancements in engine technology can also provide opportunities for upgrading systems, ultimately supporting better performance across all aspects of oilfield operations.

Key Features of High-Performance Oilfield Engines

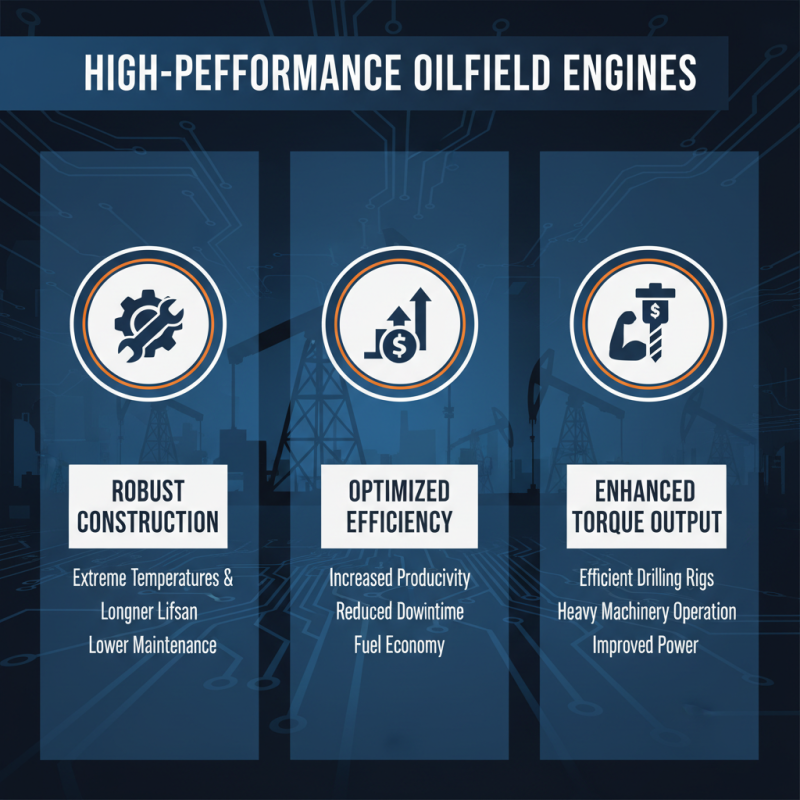

High-performance oilfield engines are crucial for optimizing efficiency and productivity in the demanding environment of oil extraction. One of the key features of these engines is their robust construction, which allows them to withstand extreme temperatures and pressures typically encountered in oilfields. This durability ensures a longer lifespan and lower maintenance costs, making them an economical choice for operators. Additionally, high-performance oilfield engines are designed to provide enhanced torque output, facilitating the efficient operation of drilling rigs and other heavy machinery.

Another significant aspect of high-performance oilfield engines is their advanced fuel efficiency. Improved combustion technology enables these engines to maximize energy output while minimizing fuel consumption. This not only reduces operational costs but also contributes to a more sustainable approach to energy use in the oil industry. Furthermore, many of these engines are equipped with cutting-edge monitoring systems that provide real-time data on performance metrics. This capability allows operators to make informed decisions quickly, leading to enhanced operational efficiency and productivity on-site.

Top 10 Oilfield Engines Ranked by Efficiency and Performance

In the oil and gas industry, the efficiency and performance of engines play a critical role in enhancing operational capabilities. Recent reports indicate that engines specifically designed for oilfield applications exhibit significant advancements in fuel efficiency, reducing operational costs by as much as 20-30%. For example, engines utilizing advanced combustion technologies can deliver higher torque at lower RPMs, which not only improves power output but also extends maintenance intervals due to reduced wear and tear.

Moreover, the integration of real-time monitoring systems has transformed how oilfield engines operate. According to the Society of Petroleum Engineers, engines equipped with smart diagnostics have shown a 15% improvement in overall uptime. This is largely due to predictive maintenance, allowing operators to address potential issues before they lead to engine failure. An emphasis on lightweight materials and enhanced design also contributes to improved thermal efficiency, enabling these engines to perform optimally even in the most challenging environments.

The ranking of oilfield engines by their efficiency and performance metrics highlights the importance of choosing the right technology for specific applications. Data from industry studies demonstrate that the top-performing engines not only meet stringent emissions standards but also provide operational flexibility that can adapt to various drilling and extraction needs. By prioritizing these engines, companies can significantly boost productivity while minimizing their ecological footprint, aligning with the industry's shift towards sustainability.

Top 10 Oilfield Engines Ranked by Efficiency and Performance

Maintenance Practices for Maximizing Oilfield Engine Longevity

Effective maintenance practices are crucial for maximizing the longevity of oilfield engines. Regular inspections and routine maintenance schedules help identify potential issues before they escalate into costly repairs or operational downtime.

Implementing a daily checklist to monitor essential components such as filters, oil levels, and coolant status ensures that any abnormalities are addressed promptly. Keeping accurate maintenance records can also aid in tracking the performance of the equipment over time, allowing for data-driven decisions regarding upgrades or replacements.

Additionally, the lubrication of moving parts cannot be overstated. Using the appropriate lubricants and following recommended change intervals is key to reducing friction and wear. Moreover,

implementing an engine performance monitoring system can provide real-time insights into engine health, allowing operators to optimize performance while preventing failures.

Educating personnel on proper handling and operational techniques further minimizes the risk of accidental damage, enhancing the overall lifespan and efficiency of the engines in oilfield operations.

Future Innovations in Oilfield Engine Technology and Their Impact

The oilfield engine technology landscape is undergoing a significant transformation, driven by advancements aimed at enhancing efficiency and performance. Recent reports indicate that the oil and gas industry is projected to invest over $200 billion in technology upgrades by 2025, focusing heavily on engine optimization and automation. These innovations are not only reducing operational costs but also minimizing environmental impact through improved fuel efficiency and reduced emissions. For instance, the integration of artificial intelligence and machine learning into engine systems enables real-time data analysis, leading to predictive maintenance that can cut downtime by as much as 30%.

Moreover, the push towards alternative fuels is reshaping engine technology in oilfields. According to the International Energy Agency, the adoption of biofuels and renewable energy sources could account for up to 20% of the total energy supply in the sector by 2040. This shift is prompting the development of hybrid engines that can seamlessly transition between traditional fossil fuels and cleaner alternatives. These innovations not only address sustainability challenges but also align with regulatory trends, ensuring that oilfield operations remain viable in an increasingly eco-conscious market. By embracing these future innovations, companies can significantly enhance their operational efficiency and sustain long-term growth while meeting environmental standards.

Related Posts

-

What is the Future of Oilfield Equipment in a Changing Energy Landscape?

-

Unlocking Efficiency: The Rise of Natural Gas Engines in Sustainable Transportation Solutions

-

5 Best Industrial Machine Equipment Innovations You Should Know

-

Exploring Innovative Examples of Industrial Supplies and Equipment for Modern Manufacturing

-

How to Optimize Your Operations with a Natural Gas Machine

-

The Future of Industrial Supplies and Equipment in a Sustainable World