Top 10 Oilfield Equipment You Need to Know About?

In the ever-evolving landscape of the oil industry, understanding essential oilfield equipment is crucial. John Smith, a leading expert in oilfield operations, emphasizes, "Choosing the right equipment can make or break an operation." This insight reminds us of the importance of selecting tools that not only perform well but also ensure safety.

Oilfield equipment encompasses a wide range of tools and machinery. These include drilling rigs, blowout preventers, and separators. Each piece plays a vital role in optimizing production while minimizing risks. However, it’s easy to overlook the intricate details that contribute to overall effectiveness. Even seasoned professionals sometimes underestimate the impact of outdated equipment.

It's essential to reflect on both innovation and tradition in this field. New technologies emerge rapidly, yet, some older equipment still remains relevant. Balancing the new with the tried-and-true requires constant reevaluation. The landscape of oilfield equipment continues to shift, challenging both experts and newcomers to adapt. This is more than a knowledge test; it’s a practical application of skills and judgment in the oil and gas sector.

Top 10 Essential Types of Oilfield Equipment and Their Functions

In the oil and gas industry, understanding essential equipment is crucial. Oilfield equipment plays a vital role in extraction and production. Key equipment includes drilling rigs, which facilitate the initial drilling process. These rigs can cost millions, impacting overall project budgets.

Pumps are another critical component. They move fluids from the ground to the surface. According to a recent report, over 30% of operational costs are linked to pumping systems. Maintenance is key to efficiency. Regularly check seals and bearings to prevent downtime.

Storage tanks store crude oil and other fluids safely. Their design must meet specific regulations. A failure in a tank can lead to significant environmental hazards. Regular inspections are essential, although costly.

**Tip:** Always invest in training programs for your team. Proper training can drastically reduce accidents and improve productivity.

Separators are crucial for processing oil and gas mixtures. They separate liquid from gas, ensuring purity for transport. Efficiency in separators contributes to nearly 25% of processing effectiveness.

**Tip:** Implement a lifecycle management plan for your equipment. This helps in understanding when to repair or replace equipment before failures occur.

Lastly, compressors help in transporting natural gas. Neglecting their maintenance can lead to performance issues, resulting in lost revenue. Regular checks are necessary to keep them running smoothly.

Top 10 Essential Types of Oilfield Equipment and Their Functions

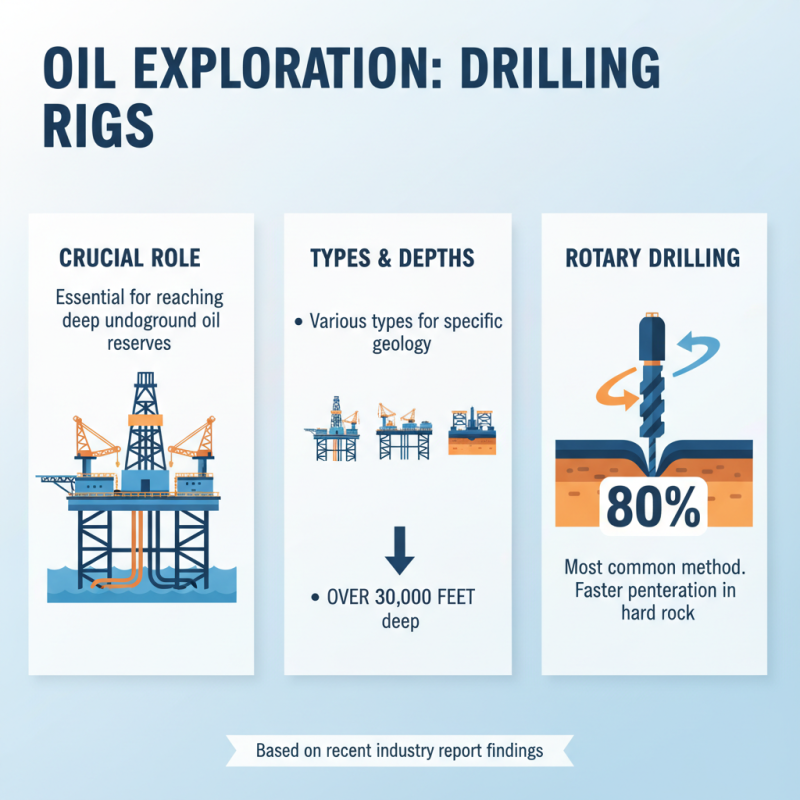

Key Features and Specifications of Drilling Rigs in Oil Exploration

In oil exploration, drilling rigs play a crucial role. These rigs come in various types, each designed for specific geological conditions. Most modern drilling rigs can reach depths of over 30,000 feet. According to a recent industry report, approximately 80% of drilling operations are conducted using rotary drilling methods. This technique allows for faster penetration of hard rock formations.

Key features to consider include the rig's power system and the type of drilling equipment used. A typical rig can generate around 1,500 horsepower. This power is essential for operating the drill and rotating the drill pipe. Safety features are also critical. Reports indicate that failure to adhere to safety protocols can result in serious accidents. Inadequate training for operators can exacerbate risks.

The specifications of drilling rigs vary widely. Some rigs use advanced technology like automated drilling systems. This can enhance precision and reduce operational costs. However, technology is not foolproof. Instances of equipment malfunction can lead to delays. Analyzing performance data is vital for ongoing improvements. It's important to remember that even the best rigs require regular maintenance to operate effectively.

Impact of Downhole Tools on Well Performance and Oil Recovery Rates

Downhole tools play a crucial role in enhancing well performance and oil recovery rates. These specialized tools are crucial during drilling and production phases. According to the International Energy Agency, effective use of downhole tools can improve oil recovery rates by up to 15%. This increase can greatly affect overall production efficiency.

The choice of tools directly influences well performance. For instance, the right drill bit can reduce drilling time significantly. Studies show that faster drilling leads to reduced operational costs. However, not all tools perform equally in different geological formations. This inconsistency can pose challenges. Operators often face unexpected issues during deployment.

Moreover, integrating advanced technologies into downhole equipment can be daunting. Real-time data monitoring is essential for making informed decisions. A report by the Society of Petroleum Engineers highlighted that many companies overlook data analysis. This often leads to suboptimal performance. While some operators invest significantly in technology, others may resist modernization. This can hinder potential gains in recovery rates, underscoring a need for reflection and strategy adjustment in the industry.

Role of Pumping Equipment in Oil Production and Flow Assurance

Pumping equipment plays a critical role in oil production. It ensures a steady flow of oil from reservoirs to processing facilities. Without effective pumps, the extraction and transportation of oil would face significant challenges. These challenges can lead to delays and increased operational costs.

The types of pumping equipment vary widely. Each type has its specific function and application. For instance, positive displacement pumps suit high-viscosity fluids. They create pressure to move oil efficiently. On the other hand, centrifugal pumps are ideal for low-viscosity fluids. They can handle large volumes quickly. However, selecting the right pump is not always straightforward.

Factors such as reservoir conditions and flow rates complicate the decision-making process.

Flow assurance relies heavily on these pumps. They must maintain consistent pressure and prevent blockages in pipelines. Even minor faults can disrupt production significantly. Decision-makers must often revisit their choices and strategies. This includes evaluating pump performance and maintenance schedules. Regular inspection is essential to avoid unexpected failures. By doing so, operators can ensure that production runs smoothly and effectively.

Latest Technological Advancements in Oilfield Equipment for Efficiency

In the ever-evolving oilfield sector, technological advancements play a crucial role. Innovations in equipment improve efficiency and safety, directly impacting productivity. Automated drilling systems, for example, reduce human error and streamline operations. This efficiency often leads to significant cost reductions. Real-time data monitoring is another key advancement. It allows operators to make informed decisions, adjusting processes instantly based on conditions.

Consider implementing remote monitoring tools. These enhance safety by allowing teams to track equipment from afar. This can minimize the need for personnel in potentially hazardous environments. Additionally, investing in advanced sensors can help maintain equipment. These sensors predict failures early, saving time and repair costs.

Evaluate your current equipment regularly. Upgrading to more efficient technology can yield better results. But remember, it’s not just about the latest gadgets. Training staff on new systems is vital. Knowledge and adaptability are just as important as technology for maximizing efficiency. Aim for a balance between human skill and machine capability.

Top 10 Oilfield Equipment You Need to Know About - Latest Technological Advancements in Oilfield Equipment for Efficiency

| Equipment Name | Key Features | Technological Advancements | Efficiency Improvements |

|---|---|---|---|

| Rotary Drilling Rig | High torque capabilities | Automated drilling systems | Increased drilling speed by 20% |

| Mud Systems | Advanced filtration technology | Real-time monitoring sensors | Reduced mud waste by 30% |

| Wellhead Systems | Enhanced safety features | Smart valves with IoT connectivity | Optimized production efficiency |

| Completion Equipment | Modular design for quick assembly | Hydraulic fracturing technology | Improved resource extraction |

| Production Separator | Multi-phase separation | AI integration for process optimization | Increased recovery rate by 15% |

| Pipeline Inspection Tools | Robotic inspection units | Data analytics for failure prediction | Prevention of leaks and bursts |

| Artificial Lift Systems | Electromechanical systems | Smart monitoring technology | Higher production uptime |

| Safety Equipment | Personal protective gear | Wearable safety technology | Reduced accident rates |

| Fracking Equipment | Customized pumps | Advanced fluid mixing technology | Enhanced fracture conductivity |

| Enhanced Oil Recovery Tools | Chemical injection systems | Modeling software for optimization | Increased oil recovery by 25% |

Related Posts

-

How to Select the Right Industrial Gas Compressor for Your Business Needs

-

The Ultimate Guide to Choosing the Right Industrial Machinery and Equipment for Your Business

-

How to Choose the Right Industrial Equipment for Your Business Needs

-

Uncovering the Advantages of Industrial Machine Equipment in Enhancing Global Supply Chain Efficiency

-

Top Oilfield Production Equipment Trends to Watch in 2025

-

Mastering Industrial Shop Equipment A Comprehensive Guide for Beginners