Unlocking Efficiency: How Industrial Gas Compressors Revolutionize Modern Manufacturing

In contemporary manufacturing, the role of industrial gas compressors has become increasingly pivotal in enhancing operational efficiency and productivity. According to a report by MarketsandMarkets, the global industrial gas compressor market is projected to reach $22.5 billion by 2026, driven by the growing demand for compressed air and gas in various sectors such as food and beverage, healthcare, and automotive. These compressors not only optimize production processes but also contribute to energy savings and sustainability efforts, which are crucial in today’s eco-conscious landscape. By enabling precise control of gas flow and pressure, industrial gas compressors facilitate the smooth running of complex manufacturing systems, resulting in reduced downtime and increased throughput. As industries continuously seek ways to improve and innovate, the transformative impact of industrial gas compressors is evident, marking them as essential components in the future of modern manufacturing.

Understanding the Basic Principles of Industrial Gas Compressors and Their Functionality

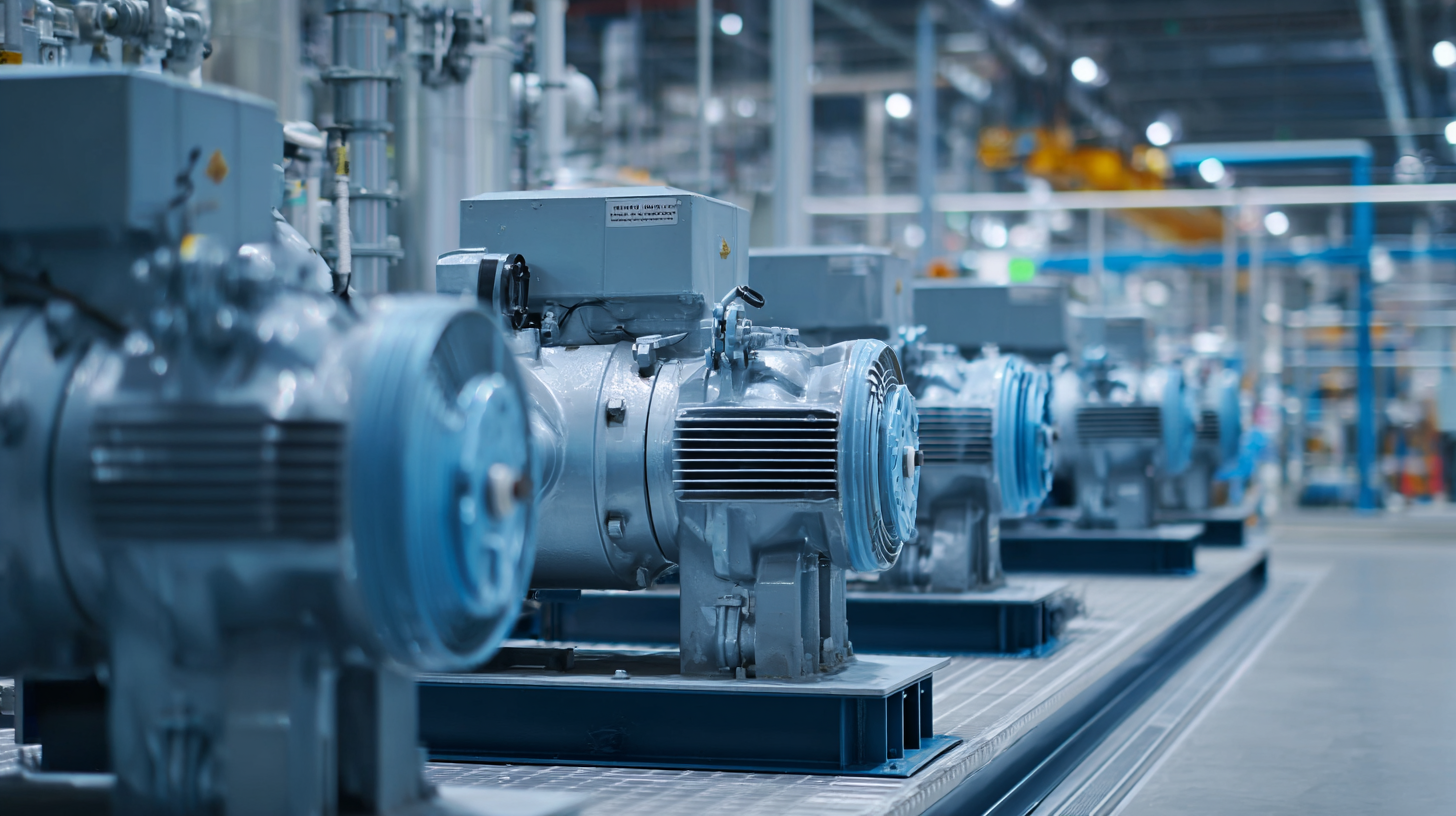

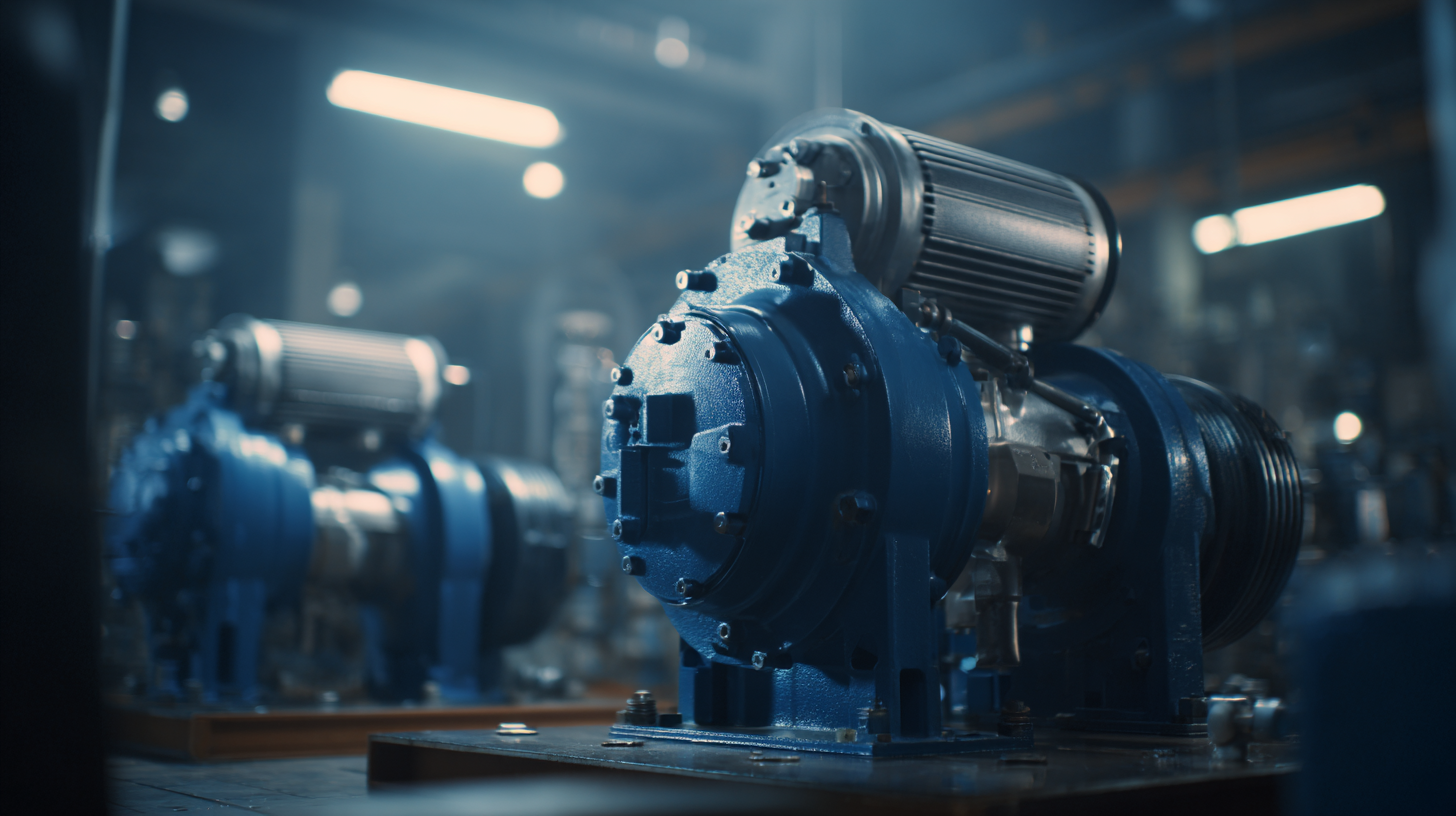

Industrial gas compressors are essential components in modern manufacturing, enabling a variety of processes by converting power into pressurized gas. These machines operate on fundamental principles of physics, utilizing either positive displacement or dynamic compression methods.

Positive displacement compressors work by trapping a certain volume of gas and reducing its volume, thereby increasing pressure. In contrast, dynamic compressors accelerate the gas using high-speed rotating blades, which then converts the kinetic energy into pressure as the gas exits the compressor.

The functionality of industrial gas compressors extends beyond mere gas compression. They play a critical role in applications such as pneumatic conveying systems, refrigeration, and power generation. By ensuring a consistent flow of compressed air or gas, these compressors enhance operational efficiency and reliability in manufacturing processes. Moreover, advancements in technology have led to more efficient designs, reducing energy consumption and improving overall productivity. This revolution in compressor technology has made it possible for manufacturers to optimize their operations, resulting in significant cost savings and a smaller environmental footprint.

Identifying Key Benefits of Implementing Gas Compressors in Manufacturing Processes

In the realm of modern manufacturing, the integration of industrial gas compressors offers substantial advantages that enhance operational efficiency. By optimizing production processes, gas compressors facilitate better energy management, reducing energy consumption significantly. For instance, as highlighted in recent studies, innovative approaches to energy recovery and optimization in gas compression facilities have demonstrated potential annual savings of nearly $1.9 million in fuel consumption alone. This reduction not only lowers operational costs but also contributes to a more sustainable manufacturing framework.

In the realm of modern manufacturing, the integration of industrial gas compressors offers substantial advantages that enhance operational efficiency. By optimizing production processes, gas compressors facilitate better energy management, reducing energy consumption significantly. For instance, as highlighted in recent studies, innovative approaches to energy recovery and optimization in gas compression facilities have demonstrated potential annual savings of nearly $1.9 million in fuel consumption alone. This reduction not only lowers operational costs but also contributes to a more sustainable manufacturing framework.

Moreover, the implementation of advanced technologies, such as Organic Rankine Cycle (ORC) systems for waste heat recovery, further underscores the transformative impact of gas compressors in the industrial sector. These technologies not only improve energy efficiency but also help companies minimize their carbon footprints, aligning with the global push towards greener manufacturing practices. The strategic use of gas compressors is thus pivotal, enabling manufacturers to not only enhance their productivity but also address pressing environmental challenges.

Exploring Different Types of Industrial Gas Compressors and Their Applications

The industrial gas compressor market is experiencing significant growth, driven by advancements in technology and increasing demand across various sectors. The global HVAC centrifugal compressor market, for instance, surpassed $900 million in size in 2016, and it is expected to continue expanding as manufacturers look for more efficient solutions. Additionally, the market for multi-stage steam turbines, particularly those below 5000 kW, is projected to rise from $18.16 billion in 2024 to $28.06 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.62%. This growth indicates a robust trend towards embracing energy-efficient technologies within industrial applications.

Other key segments include the air conditioning compressor market, which is forecasted to reach $24.3 billion by 2032, with a CAGR of 3.73%. Likewise, the diaphragm compressor market is expected to grow from $720 million in 2025 to $1.92 billion by 2034, at an impressive rate of 11.56%. This trajectory showcases the diversification of compressor technologies catering to both industrial and commercial needs, enhancing process efficiency and sustainability within modern manufacturing environments. The growing emphasis on electrochemical processes and refrigeration systems further illustrates the industry's commitment to reducing carbon footprints while meeting the increasing demand for industrial gas through innovative compression solutions.

Unlocking Efficiency: How Industrial Gas Compressors Revolutionize Modern Manufacturing

| Compressor Type | Max Pressure (psi) | Power Consumption (kW) | Typical Applications |

|---|---|---|---|

| Reciprocating Compressor | 1000 | 15-200 | Petrochemical, Food Processing |

| Rotary Screw Compressor | 150-200 | 10-300 | Manufacturing, Automotive |

| Centrifugal Compressor | 300-600 | 50-1500 | Chemical Plants, HVAC Systems |

| Diaphragm Compressor | 60-100 | 5-50 | Laboratories, Medical Applications |

| Scroll Compressor | 50-100 | 1-15 | Refrigeration, Air Conditioning |

Best Practices for Maintaining and Optimizing Gas Compressor Performance

Maintaining and optimizing gas compressor performance is crucial for ensuring efficiency in modern manufacturing. One of the best practices is to implement a proactive maintenance schedule. Regularly inspecting components such as filters, valves, and bearings can prevent unexpected downtime and extend the lifespan of the compressor.

Additionally, monitoring vibration and temperature levels helps identify potential issues before they escalate, allowing for timely interventions.

Additionally, monitoring vibration and temperature levels helps identify potential issues before they escalate, allowing for timely interventions.

Another key aspect is to optimize operating conditions based on the specific requirements of the manufacturing process. Adjusting parameters like pressure and flow rates can significantly enhance the compressor's efficiency. Utilizing advanced control systems and automation can facilitate real-time adjustments, ensuring that the compressor operates within its optimal range. Training staff on these best practices further supports effective troubleshooting and performance monitoring, ultimately driving productivity and cost savings in the manufacturing environment.

Innovative Technologies That Enhance the Efficiency of Modern Gas Compressors

Industrial gas compressors play a pivotal role in modern manufacturing, utilizing cutting-edge technologies to enhance operational efficiency. These innovative systems incorporate features such as variable speed drives and advanced control algorithms, which optimize energy use while adapting to fluctuating production demands. The result is a more sustainable process that minimizes waste and lowers operating costs, making it a game-changer in various industrial applications.

When considering the implementation of industrial gas compressors, manufacturers should focus on regular maintenance and monitoring to ensure optimal performance. Tips for efficiency include scheduling periodic inspections to detect potential issues before they escalate and investing in smart technology that provides real-time data on compressor performance. Additionally, utilizing systems that allow for seamless integration with existing manufacturing processes can streamline operations and enhance overall productivity.

Adopting innovative compressor technologies also means considering energy recovery options. Tips here include evaluating systems that capture and utilize waste heat from compression processes, which can significantly reduce energy consumption. By being proactive in these areas, businesses can unlock the full potential of their gas compressors, driving success in a competitive market.

Related Posts

-

The Ultimate Guide to Choosing the Right Industrial Machinery and Equipment for Your Business

-

How to Choose the Right Natural Gas Machine for Your Business Needs

-

How to Optimize Your Operations with a Natural Gas Machine

-

Innovative Strategies for Enhancing Oilfield Production Equipment Efficiency

-

Exploring Innovative Examples of Industrial Supplies and Equipment for Modern Manufacturing

-

Ultimate Guide to Selecting the Right Oil Field Machine for Your Operations